Fracture Toughness Testing is required for the material used in aerospace, automotive, power generation, and medical industries to estimate the crack growth and fracture toughness studies.

Many applications exist where a material is subjected to a repeated cyclic stress. These materials are found to fail after a large number of applications of the stress even though the cyclic stress that is applied is below their yield strength. This mode of failure is termed fatigue. The reason that these materials fail is due to progressive stepwise crack growth through the sample. Cracks create stress concentrations that raise the level of stress to a level above the yield strength of the material in the vicinity of the crack. Repeated cyclic stresses propagate the crack until failure.

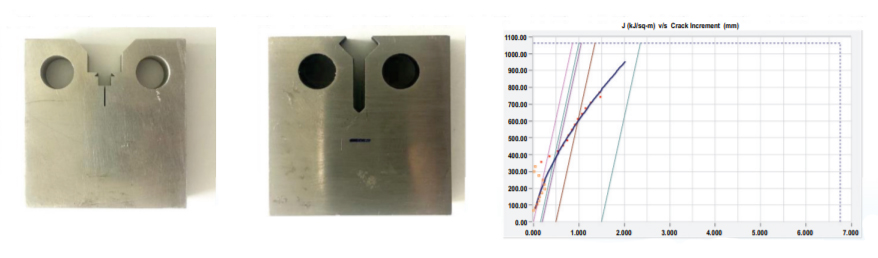

There are two types of fracture toughness tests viz., Plane Strain Fracture Toughness (K1c) and Elastic Plastic Fracture Toughness (J1c). The standards that cover Fracture Mechanics testings: ASTM Standard E 647 (Fatigue Crack Growth Rate), E 399 (K1c) and E1820 (J1c).