Universal Testing Machines (UTM) – A Comprehensive Guide on Price, Usage, and Standards

Universal Testing Machines (UTMs) play a crucial role in material testing, offering the ability to evaluate the tensile and compressive strength of materials. This blog covers various aspects such as UTM prices, suppliers, testing services, standards, and calibration. Whether you are looking for UTM suppliers in India or need information on tensile testing standards, this guide has you covered.

The price of a Universal Testing Machine (UTM) depends on its specifications, load capacity, and features. Standard UTM machines for basic testing typically range between ₹3 lakh to ₹15 lakh. High-capacity or Digital Universal Testing Machines with advanced features can go up to ₹50 lakh or more. For automated or custom Universal Testing Machines, the price could vary even further, based on the customizations required.

Tensile testing machine price: ₹2.5 lakh to ₹10 lakh.

UTM machine price: ₹3 lakh to ₹50 lakh, depending on capacity and automation.

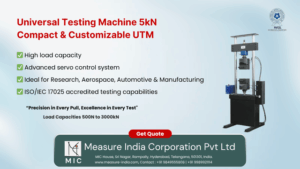

UTMs come with various load capacities to suit different testing needs. The load capacity typically ranges from 5 kN to 5000 kN. Larger load capacity UTMs are used for testing stronger materials like metals, while smaller ones are ideal for plastics, rubber, and other lightweight materials.

Several manufacturers and suppliers provide quality Universal Testing Machines in India. Some prominent UTM suppliers and UTM dealers near you may include companies like:

If you are looking for material testing labs near you, many NABL-accredited labs across India provide UTM testing services, including tensile testing, compression testing, and more. These labs adhere to national and international standards, offering precision testing services.

A Universal Testing Machine works on the principle of applying a force to a material specimen until it breaks or deforms. The UTM consists of two main parts: a loading unit and a control unit. The specimen is placed in the grips, and force is applied either through hydraulic or mechanical means. The machine measures the force applied and the elongation or deformation of the material.

UTMs adhere to several international standards:

These standards ensure consistency and accuracy in material testing across industries.

The ASTM standards for UTMs are widely used globally for testing materials like metals, plastics, and textiles. Common ASTM standards include:

ASTM E4: For calibration of UTMs.

ASTM E8: For tensile testing of metals.

Regular calibration is essential for the accurate functioning of a UTM. Calibration services ensure that the machine is measuring force and displacement correctly. The basic steps for calibrating a Universal Testing Machine include:

UTM calibration services are offered by NABL-accredited laboratories like Measure India Corporation Pvt Ltd.

Routine maintenance of your UTM ensures long-lasting performance. Key maintenance tips include:

Digital UTMs come equipped with advanced electronics and software for real-time data collection and analysis. Automated UTMs take this further by offering completely automatic loading and testing processes, reducing human intervention and increasing accuracy.

Many manufacturers offer custom Universal Testing Machines that can be tailored to specific industry needs, including load capacity, testing environment, and automation features.

Office Address

MIC House, SreeNagar, Rampally,

Hyderabad – 501301, Telangana, India

Website: www.measure-india.com

Phone: +91-9989921114

Email: info@measure-india.com