Tensile Testing Machine for Material Strength Analysis

Tensile testing machines, also known as universal testing machines (UTMs), are essential for assessing the strength, elasticity, and durability of materials. These machines are designed to measure the material’s ability to withstand force when stretched or pulled, offering valuable data such as the breaking point, elongation, and tensile strength. Tensile testing is fundamental for industries like construction, aerospace, automotive, and manufacturing to ensure material performance and safety.

Quality Control: Tensile testing ensures that products meet industry standards, providing reliable performance in real-world applications.

Research & Development (R&D): These machines play a key role in developing new materials by evaluating their mechanical properties and behavior under stress.

Safety Standards: Tensile testing helps confirm that materials can handle the required load-bearing capacities without failure, preventing potential accidents and ensuring product safety.

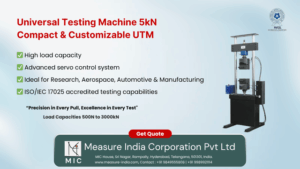

Universal Testing Machine (UTM): A versatile solution for testing various materials, the UTM is designed to accommodate different crosshead sizes, making it ideal for applications in diverse industries like aerospace, automotive, and construction.

Digital Tensile Testing Machine: Equipped with advanced electronic sensors and software, these machines allow for precise real-time data analysis, offering accuracy and automation for high-performance testing.

Uniaxial Testing Machine: This machine is best suited for testing isotropic materials under uniaxial stress conditions, ensuring high precision in measuring the material’s strength in one direction.

High Sensitivity: Accurate measurements of load and elongation, crucial for precise material testing.

User-Friendly Interface: Intuitive control panel for easy operation and setup, suitable for both novice and expert users.

Versatility: Capable of testing a wide range of materials including metals, plastics, rubber, textiles, and composites.

Durability & Reliability: Built to handle demanding testing conditions, ensuring long-term, consistent performance.

There are different types of centrifugal compressors, categorized based on the number of compression stages:

Single-stage centrifugal compressors – Used in HVAC systems and industrial air compression, where a moderate pressure increase is sufficient.

Multi-stage centrifugal compressors – Designed for high-pressure applications, such as gas processing, LNG plants, and chemical industries, where gas must be compressed multiple times before reaching the desired output pressure.

Measure India Corporation Pvt. Ltd. is a renowned manufacturer of high-quality tensile testing machines. With over 20 years of experience, the company offers universal testing machines designed to deliver precise and reliable testing for materials across various industries. Their products are known for their durability, accuracy, and versatility, making them ideal for quality control, research, and development applications in industries like aerospace, automotive, biomedical, and construction.

High-precision testing for tensile strength, elongation, and breaking point.

Customizable configurations to suit specific industry needs.

Advanced control systems for real-time data analysis and reporting.

Built to withstand rigorous testing environments.

Load Capacity: Ensure the machine can apply the necessary force for testing the materials relevant to your industry.

Accuracy: Choose a machine capable of providing highly accurate measurements for force and elongation.

Control Systems: Look for machines with digital control and data collection systems to simplify data processing and improve efficiency.

Versatility: Opt for machines capable of testing a wide range of materials to meet the requirements of various applications.

Automation: The latest tensile testing machines come with automated operation, minimizing human error and increasing efficiency in material testing.

Real-Time Data Analysis: New machines provide instant reporting and analysis, enabling quick decision-making and reducing testing turnaround time.

Environmental Chambers: Some advanced models include environmental chambers that simulate real-world conditions like temperature and humidity, making them ideal for testing materials in extreme environments.

Selecting the right tensile testing machine is vital to ensure the quality, safety, and performance of your materials. Whether you’re involved in research, development, or quality control, investing in a high-performance machine ensures that your materials meet stringent industry standards. By choosing a machine with the right features, accuracy, and load capacity, you can streamline your testing processes and ensure material reliability.

Office Address : Tensile Testing Machine Price & Suppliers in India

MIC House, Sree Nagar, Rampally,

Hyderabad – 501301, Telangana, India

Website: www.measure-india.com

Phone: +91-9989921114

Email: info@measure-india.com