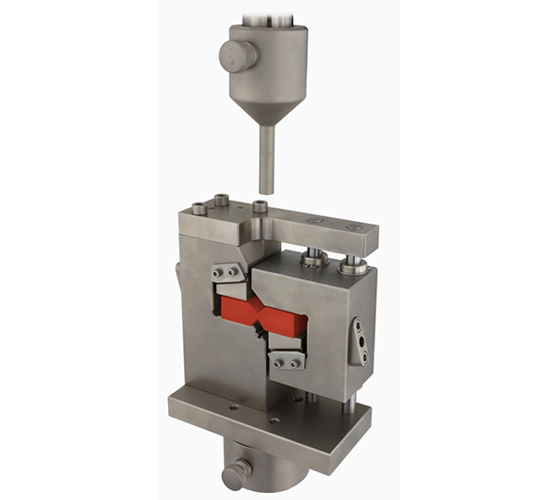

Shear Fixtures Applications

Shear Fixtures are essential components used in Universal Testing Machines (UTMs) to accurately measure the shear strength and behavior of materials when subjected to forces parallel to the material surface. These fixtures are designed to secure specimens during shear testing, ensuring that materials are tested under controlled conditions for precise and reliable results. Below are the key applications of Shear Fixtures:

Applications:

Shear Strength Testing: Shear Fixtures are primarily used to evaluate the shear strength of materials by applying force parallel to the material’s surface. These fixtures are ideal for testing a variety of materials, including metals, plastics, composites, and adhesives, to determine their resistance to shearing forces.

Adhesive Bond Testing: These fixtures are widely used in testing the shear strength of adhesive bonds in materials such as films, laminates, and coatings. This is critical for assessing the bonding efficiency of adhesives used in industries like automotive, aerospace, and electronics.

Composite Material Testing: Shear Fixtures are essential for testing composite materials, especially those used in aerospace, automotive, and construction industries. These materials, such as fiber-reinforced composites, are subjected to shear forces to evaluate their performance under stress.

Foam Testing: Shear Fixtures are used in testing foams and soft materials, measuring their resistance to shear forces, which is important in industries like packaging, automotive, and construction.

Rubber and Elastomer Testing: These fixtures are used for testing the shear properties of rubber and elastomer materials, essential for evaluating their performance in applications such as seals, gaskets, and tires.

Textile Testing: Shear Fixtures are used in the textile industry to measure the shear strength of fabrics and textiles, which is crucial for evaluating their durability, stretchability, and overall performance.

Plastic and Polymer Testing: These fixtures are ideal for testing plastics and polymers, where shear forces are applied to evaluate their shear modulus, resistance, and performance under load.

Coatings and Paints Testing: Shear Fixtures are used to test the adhesion and shear strength of coatings, paints, and surface treatments, which are important for applications in automotive, aerospace, and industrial sectors.

Metal Testing: Shear Fixtures are used to test metals in shear, providing insights into their material properties and behavior under stress, such as testing thin metal sheets, strips, and foils.

Packaging Material Testing: These fixtures are applied to test packaging materials like films, foils, and papers for shear strength, helping assess their ability to withstand forces during handling and transportation.

Biomedical and Medical Device Testing: Shear Fixtures are used in testing the shear strength of biomaterials, medical devices, and implants, ensuring they meet the necessary specifications for patient safety and performance under stress.

Wood and Lumber Testing: Used in testing wood samples and lumber, Shear Fixtures help evaluate their shear strength and resistance to cracking or failure under stress, essential for structural applications.

Advantages of Shear Fixtures:

Precise Force Application: Shear Fixtures ensure that shear forces are applied uniformly and accurately, providing reliable test results.

Versatile Testing: These fixtures can be used with a wide range of materials, making them suitable for various industries, from aerospace to packaging and construction.

Easy Setup: The fixtures are designed for easy integration into Universal Testing Machines, allowing for quick and efficient setup and testing of shear properties.

Durability: Built with high-quality materials, Shear Fixtures are designed to withstand repetitive testing while maintaining consistent performance.

Accurate and Repeatable Results: These fixtures ensure that shear tests are conducted under controlled conditions, providing accurate and repeatable results that are essential for quality assurance and material testing.

Cost-Effective Solution: Shear Fixtures provide a reliable and affordable solution for industries requiring shear testing, ensuring that companies get the most value from their testing equipment.

Industry Applications:

Automotive Industry: Used to test the shear strength of materials and components in the automotive industry, such as adhesives, seals, and composite parts, to ensure safety and performance under stress.

Aerospace Industry: Applied in aerospace material testing, especially for composites and adhesive bonds, ensuring components meet the rigorous shear strength requirements for flight safety.

Construction and Building Materials: Shear Fixtures are used to test construction materials like concrete, wood, and composites for shear strength, which is vital for structural integrity and safety.

Packaging Industry: Essential for testing packaging materials such as films, foils, and papers, ensuring their durability and performance under stress during handling and transportation.

Consumer Goods and Electronics: Used to test the shear strength of materials used in consumer products and electronics, ensuring they are durable and reliable for everyday use.

Biomedical and Medical Device Testing: Widely used in testing biomaterials, medical implants, and devices to ensure they meet the necessary shear strength requirements for patient safety and longevity.

Textile Industry: Shear Fixtures are used to evaluate the shear properties of textiles, fabrics, and garments, ensuring they meet performance standards for strength and durability.

Shear Fixtures are vital tools for laboratories and industries that require accurate and consistent shear testing. Their versatility, precision, and durability make them an indispensable part of Universal Testing Machines, ensuring reliable results in a wide range of material testing applications.