The R.T. Extensometer is a high-accuracy universal testing machine accessory designed to measure strain during tensile, compression, and cyclic tests. Its advanced features make it suitable for precise material testing in compliance with industry standards.

universal testing machine accessories, universal testing machine price, accessories, extensometer, strain measurement, material testing extensometer, tensile testing accessory.

The R.T. Extensometer is a precision instrument designed to measure strain in materials during tensile, compression, or flexural testing conducted on universal testing machines. This extensometer provides accurate and repeatable measurements of material deformation under applied forces, making it an essential tool for evaluating mechanical properties such as modulus of elasticity, yield strength, and elongation.

Engineered for reliability and versatility, the R.T. Extensometer is ideal for use across various industries, including aerospace, automotive, construction, and materials research. Its robust design allows it to accommodate a wide range of specimen sizes and shapes, ensuring compatibility with metals, polymers, composites, and other materials.

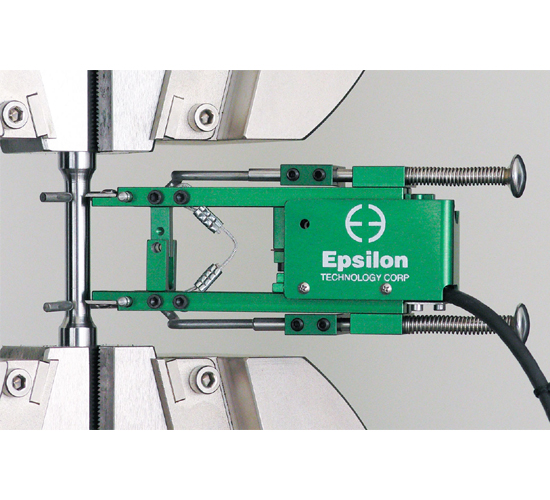

The R.T. Extensometer features high-resolution sensors that capture precise strain data, even during high-load or high-speed tests. Its spring-loaded attachment system ensures a secure and stable connection to the specimen, minimizing measurement errors caused by slippage or misalignment. The device is constructed from durable materials that withstand demanding testing environments, ensuring long-term reliability.

This extensometer is easy to install and operate, with adjustable settings to suit different testing requirements. It is compatible with most universal testing machines and integrates seamlessly with software, providing real-time strain data for comprehensive analysis and reporting.

Whether used for basic tensile tests or advanced research applications, the R.T. Extensometer delivers accurate and dependable results. For more information on the R.T. Extensometer, customization options, and universal testing machine price, contact us today

R.T. Extensometer Features

The R.T. Extensometer is a reliable and precise tool for strain measurement, enhancing the capabilities of universal testing machines and ensuring accurate data for material testing in research and industrial applications.

R.T. Extensometer Specifications:

The R.T. Extensometer is a precision instrument used in Universal Testing Machines (UTMs) to measure strain during mechanical testing. This extensometer is particularly effective in capturing real-time elongation data, ensuring accuracy and reliability in material property evaluation. Its versatile design makes it suitable for testing a wide range of materials and applications.

Tensile Testing of Metals:

The R.T. Extensometer is used to measure strain in metallic materials during tensile testing, helping determine key properties such as yield strength, tensile strength, and modulus of elasticity.

Plastic and Polymer Testing:

Essential for testing plastics and polymers, this extensometer accurately measures deformation, enabling engineers to evaluate ductility, elongation, and stress-strain behavior.

Composite Material Testing:

Widely used for measuring strain in fiber-reinforced composites, the extensometer helps analyze material behavior under load, particularly for industries like aerospace and automotive.

Rubber and Elastomer Testing:

The R.T. Extensometer is ideal for evaluating the elastic properties of rubber and elastomers, measuring their ability to stretch and return to their original shape.

Thin Film and Foil Testing:

Used for testing the mechanical properties of thin films and foils, such as those found in electronics or packaging materials, this extensometer ensures precise strain measurement.

Biomedical Applications:

In the biomedical field, the extensometer is used to test the mechanical properties of biomaterials like tissues, implants, and medical devices, ensuring they meet safety and performance standards.

Adhesive and Bonding Material Testing:

Measures strain during the testing of adhesives and bonding materials, particularly in lap shear or peel tests, to evaluate their performance under stress.

Wire and Cable Testing:

Applied for strain measurement during tensile testing of wires, cables, and strands, ensuring compliance with industry standards for strength and ductility.

Textile and Fabric Testing:

Used to measure elongation in textiles and fabrics, the extensometer provides critical data on material durability and stretchability.

Construction Material Testing:

Ensures accurate strain measurement for materials like concrete, wood, and lumber during compression or tensile tests to evaluate their structural integrity.

The R.T. Extensometer is an essential tool for laboratories and industries that require precise strain measurements during mechanical testing. Its versatility, accuracy, and durability make it a trusted choice for improving material quality and performance across various applications.

The ADMET R.T. Extensometer (Room Temperature Extensometer) is a precision instrument used to measure the elongation or strain of a specimen during mechanical testing. It is specifically designed for tensile, compression, and cyclic tests conducted at room temperature. This extensometer ensures accurate strain measurement, making it ideal for research laboratories and quality control applications.

The ADMET R.T. Extensometer attaches directly to the specimen being tested. It uses sensors or strain gauges to measure the deformation or strain as the specimen is subjected to mechanical forces. The data is then transmitted to the testing machine, which calculates the material’s stress-strain behavior.

The ADMET R.T. Extensometer is versatile and suitable for testing a wide range of materials, including:

Textiles

It provides precise strain measurement for both rigid and flexible materials.

The strain measurement range of the ADMET R.T. Extensometer depends on the specific model. Common ranges include:

High strain: Ideal for testing materials with significant elongation, such as rubbers and plastics.

Users can select a model based on their testing requirements.

Key features of the ADMET R.T. Extensometer include:

Easy attachment to specimens for efficient testing.

To attach the ADMET R.T. Extensometer:

Yes, the ADMET R.T. Extensometer is suitable for cyclic testing, where materials are subjected to repeated loading and unloading. Its robust design ensures accurate strain measurements even during dynamic tests.

The ADMET R.T. Extensometer is widely used in industries such as:

Research & Development: For studying material properties.

Advantages include:

Cost-effective solution for high-quality strain analysis.

The ADMET R.T. Extensometer typically comes with a one-year warranty covering manufacturing defects. Extended warranties may be available for specific models or upon request.