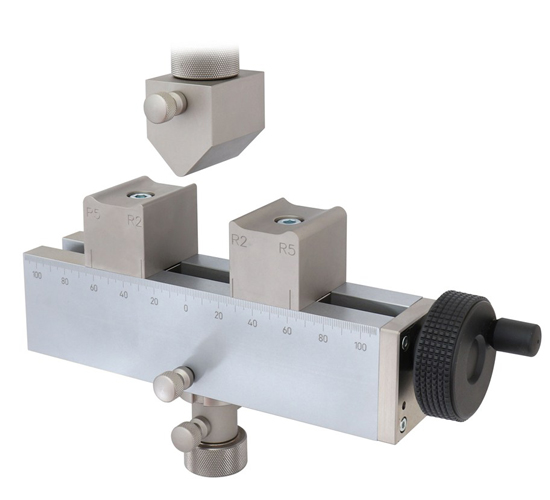

Point Bend Fixture is designed for performing bending tests, particularly for materials and components that require testing under bending stress. This fixture is commonly used in Universal Testing Machines (UTMs) to measure the flexural strength and behavior of different materials under bending loads. Below are the key applications of the Point Bend Fixture:

3-Point and 4-Point Bend Testing:

- Point Bend Fixtures are widely used for 3-point and 4-point bending tests, which are standard methods for determining the flexural strength, modulus, and ductility of materials.

- These tests are crucial in understanding how materials deform and fail when subjected to bending forces.

Plastics and Polymers:

- Used to test the flexural strength and modulus of elasticity of plastics, composites, and polymers.

- Important for quality control and material design in industries like packaging, automotive, and consumer goods.

Ceramics and Glass Testing:

- Helps determine the flexural strength of ceramics, glass, and brittle materials under bending stresses. These materials are often tested under bending loads to assess their performance under real-world conditions, such as in construction or electronics.

Metal Testing:

- The fixture is used to test the bending strength of metals and metal alloys, providing valuable data on material ductility and plastic deformation.

- Useful in industries like aerospace, automotive, and construction, where metals like steel, aluminum, and titanium are frequently tested.

Composite Materials Testing:

- Essential for testing fiber-reinforced composites, including carbon fiber and glass fiber composites.

- Used to assess bending properties and fatigue resistance of materials used in high-performance applications such as aerospace and automotive.

Wood and Lumber Testing:

- Widely used in the wood and lumber industry to measure the bending strength of various wood products, including plywood, particle board, and solid wood.

- Helps to determine the suitability of wood for construction and furniture making by evaluating its flexural modulus and strength.

Concrete Testing:

- Used for flexural testing of concrete beams and slabs to assess bending strength and crack propagation.

- Important for ensuring the structural integrity of concrete elements in construction.

Packaging Material Testing:

- Used to assess the bending resistance of packaging materials such as cardboard, paper, and films.

- Critical for ensuring the durability of packaging materials used in shipping and storage.

Rubber and Elastomer Testing:

- The fixture is used for bending tests on rubbers and elastomers to evaluate their flexibility and resilience.

- Important in the manufacturing of seals, gaskets, and other products where bending resistance is critical.

Food and Beverage Industry:

- Applied to test the bending behavior of food products such as biscuits, chips, and other snack items to determine their crunchiness or flexibility.

- Ensures that food products maintain their desired texture and are resistant to breaking during handling and packaging.

Medical Device Testing:

- Used for testing flexural strength of medical implants, prosthetics, and other medical devices made of materials such as biomaterials and metals.

- Helps assess the structural integrity of devices like bone screws, spinal implants, and orthopedic components.

Textile and Fabric Testing:

- Applied to test the flexural behavior of textiles and fabrics, particularly for materials that need to be folded, bent, or creased during use (e.g., clothing, upholstery, and fabrics for home décor).

- Helps to assess material durability under stress and ensure quality during manufacturing.

Industry Applications:

Construction and Civil Engineering:

- Used for testing construction materials like concrete beams, bricks, and steel reinforcement bars for bending strength and flexural properties.

Automotive:

- Applied to test automotive components, including chassis, suspension parts, and body panels, to ensure they can withstand bending forces during use.

Aerospace:

- Used for testing composite materials, aircraft components, and structural parts for flexural strength and fatigue resistance in harsh environments.

Medical Device Manufacturing:

- Applied to ensure orthopedic implants, medical instruments, and prosthetic limbs can endure bending forces without failure, particularly in biocompatible materials.

Packaging and Consumer Goods:

- Used in the packaging industry to test materials like cardboard, plastic films, and paper for durability and resistance to bending during storage and transportation.

Metal and Alloy Industry:

- Helps to determine the bend resistance and yield strength of metals, alloys, and thin metal sheets, crucial for industrial parts that will face bending during manufacturing or use.

Advantages of Point Bend Fixtures:

- Reliable and Accurate Testing: Provides consistent and reproducible results for flexural strength and material behavior under bending forces.

- Wide Material Compatibility: Suitable for a wide range of materials, from brittle ceramics to flexible polymers and metals.

- Durable and High-Performance: Built to withstand high bending loads while ensuring precise and accurate testing.

- Customizable Configurations: Some fixtures can be adjusted for different test setups (3-point or 4-point bend) to meet specific testing needs.

- Compliance with Standards: Meets a wide range of testing standards such as ASTM, ISO, and GB/T for various industries.

The Point Bend Fixture plays a critical role in materials testing by helping manufacturers and researchers evaluate the bending properties of materials, ensuring that products perform as expected under real-world conditions.