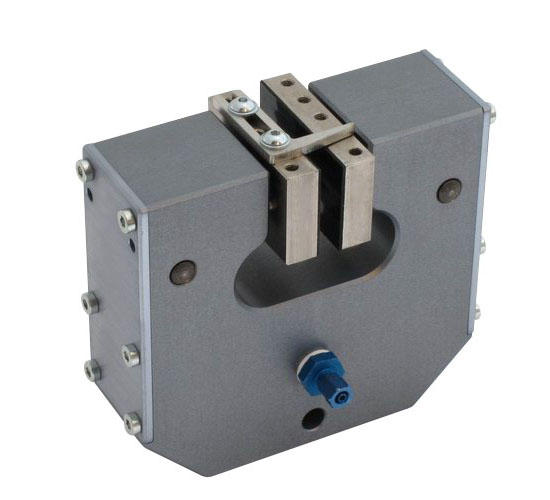

Pneumatic Grips are designed to securely hold test specimens using compressed air, providing a reliable and quick clamping mechanism. These grips are particularly useful in applications that require rapid specimen changeovers, precise force control, and minimal specimen damage. Below are the key applications for Pneumatic Grips:

Tensile Testing:

- Pneumatic grips are commonly used to hold specimens during tensile testing, where materials are subjected to pulling forces to determine their tensile strength, elongation, and other mechanical properties.

- Suitable for materials like metals, plastics, elastomers, and composites.

Compression Testing:

- Pneumatic grips can be used to securely hold materials for compression testing to assess their behavior under compressive loads.

- Ideal for materials like rubbers, foams, and certain plastics that may deform under high-pressure forces.

Peel and Tear Testing:

- Pneumatic grips ensure that materials, such as films, adhesives, and textiles, are securely held during peel and tear tests.

- These tests help evaluate the bonding strength of materials and their resistance to separation.

Fatigue and Cyclic Load Testing:

- Used in applications where the specimen undergoes repeated loading and unloading, pneumatic grips can hold materials firmly without causing damage or slippage during cyclic load testing.

- Common in testing materials like polymers, elastomers, and metals for durability.

Cyclic Stress Testing:

- Suitable for testing materials under varying stress conditions, pneumatic grips can hold specimens during tests that simulate real-world stress scenarios, such as those encountered in automotive and aerospace components.

Environmental Testing:

- Compatible with environmental chambers for high-temperature or low-temperature testing.

- Pneumatic grips hold materials securely while they are subjected to extreme environmental conditions, ensuring accuracy in tests like high-temperature tensile or compression tests.

Quick Specimen Changes:

- Pneumatic grips are ideal for applications where rapid specimen changeovers are required, such as high-throughput testing environments or production line quality control.

- The pneumatic mechanism allows for fast and easy loading and unloading of specimens.

Industry Applications:

Automotive:

- Used in automotive component testing, such as testing materials used for car interiors, tires, and structural parts under stress, strain, and fatigue conditions.

Aerospace:

- Pneumatic grips are often employed in aerospace testing for components like metals, composites, and alloys, where precision and rapid changes are necessary.

Medical Devices:

- Used to hold medical device components such as surgical instruments, implants, and bone screws during testing for tensile, compression, and fatigue strength.

Plastics and Polymers:

- Common in testing materials like films, foams, rubbers, and plastics for their tensile, tear, and fatigue resistance properties.

Textiles and Films:

- Used in the textile industry for tests like elongation, tensile strength, and tear resistance. Pneumatic grips are effective in holding thin and flexible materials such as fabrics and films.

Consumer Goods:

- Pneumatic grips are used in testing the durability and strength of various consumer products, including packaging materials, coatings, and adhesives.

Research and Development:

- Often used in R&D environments where flexibility in testing different materials with minimal downtime is required.

Advantages of Pneumatic Grips:

- Quick and Efficient: Provides fast specimen loading and unloading, making them ideal for high-throughput testing environments.

- Minimal Specimen Damage: The pneumatic system ensures a secure grip without damaging delicate or soft materials, preserving the integrity of the specimen.

- Versatile: Can be used for a wide variety of materials, from soft elastomers to tough metals and composites.

- Adjustable Clamping Force: The clamping force can be adjusted according to the material and test requirements, ensuring optimal grip without excessive deformation.

- Clean and Simple Operation: Pneumatic grips operate with compressed air, offering a clean and efficient method of specimen clamping with minimal maintenance.

Pneumatic Grips are a valuable tool for material testing, offering quick, efficient, and reliable specimen clamping for a variety of mechanical tests across industries. Whether for tensile, compression, or fatigue testing, these grips provide secure and consistent performance, improving testing efficiency and accuracy.