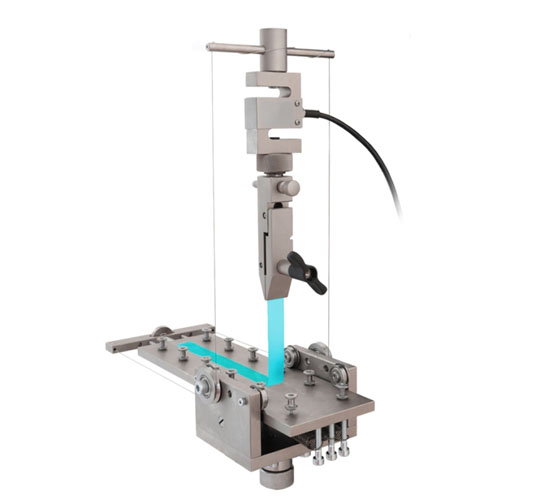

Peel Test Fixture Applications for Universal Testing Machines (UTMs)

The Peel Test Fixture is used in Universal Testing Machines (UTMs) to evaluate the adhesive strength of materials, such as films, coatings, and laminates, by measuring their resistance to peeling. The fixture is essential in industries where bonding and adhesion properties are critical to product performance. Below are the key applications of Peel Test Fixtures in various testing environments:

Applications for Universal Testing Machines (UTMs):

Adhesive Bond Strength Testing:

Peel Test Fixtures are primarily used to assess the adhesive bond strength of materials like tapes, films, adhesives, and coatings. The fixture is designed to perform peel tests, which measure how much force is required to separate two bonded materials, ensuring the adhesion properties are within specified standards.

Packaging Industry:

In packaging applications, the peel test fixture is used to evaluate the peel strength of materials such as adhesive tapes, labels, and seals. This testing is essential to ensure that packaging materials will maintain their integrity and bond strength under real-world conditions, such as during shipping or handling.

Textile and Fabric Testing:

In the textile industry, Peel Test Fixtures are used to evaluate the peel resistance of bonded fabrics and adhesives used in garments, upholstery, and industrial textiles. The testing helps to ensure the durability and strength of adhesive bonds in textile products.

Film and Coating Testing:

The fixture is ideal for testing the peel strength of films and coatings applied to various substrates. This is essential for industries like electronics, automotive, and construction, where the integrity of coatings or films directly impacts the product’s performance and longevity.

Automotive Industry:

Peel Test Fixtures are widely used in the automotive industry to assess the bonding strength of adhesive materials used in car parts, such as trim, upholstery, and exterior finishes. This helps ensure that the materials can withstand external forces during use, such as vibration, heat, and environmental exposure.

Electronics and Semiconductor Testing:

In the electronics industry, the fixture is used to test the peel strength of adhesive bonds used in components like circuit boards, displays, and electronic components. Ensuring reliable adhesion is crucial to the durability and functionality of electronic devices.

Construction and Building Materials:

Peel testing is used in construction materials to evaluate the bonding strength of coatings, films, and adhesives used in building products. This includes assessing materials like insulation films, roofing materials, and laminate flooring.

Biomedical and Medical Device Testing:

In the biomedical field, Peel Test Fixtures are used to evaluate the bond strength of adhesives in medical devices, such as wound dressings, surgical tapes, and implants. Testing ensures that adhesives used in medical products provide reliable, safe, and effective bonding under various conditions.

Foam and Insulation Testing:

For products like foam insulation, peel tests are used to assess the adhesive strength between layers of foam or foam bonded to other materials. This is particularly important in applications like packaging, insulation, and soundproofing.

Composite Material Testing:

Used for testing the peel strength of composite materials, these fixtures help assess the adhesive performance between layers in fiber-reinforced composites. This is crucial in industries like aerospace, automotive, and construction where high-performance composite materials are widely used.

Rubber and Elastomer Testing:

Peel tests are also performed on rubber or elastomer-based adhesives, especially in industries like tire manufacturing and seal production. The fixture helps evaluate the adhesive properties of rubber products used in harsh environments.

Advantages of Peel Test Fixtures:

- Accurate Adhesion Measurement: Provides precise data on the peel strength of materials, ensuring quality control for adhesive products.

- Versatility: Suitable for a wide range of materials, including films, fabrics, foams, composites, and medical devices.

- Ease of Use: Simple to integrate with Universal Testing Machines (UTMs) for streamlined testing procedures.

- Durable Construction: Built with high-quality materials to ensure consistent performance over many cycles of testing.

- Customizable Testing Configurations: Adjustable to accommodate different specimen sizes, including films, tapes, and foams.

- Cost-Effective: Provides an affordable solution for adhesion testing in research and quality control.

Industry Applications:

- Packaging Industry: Ensures the quality and durability of packaging materials such as tapes, labels, and seals.

- Automotive Industry: Assesses adhesive bonds in automotive components such as trim, upholstery, and external finishes.

- Electronics and Semiconductor Industry: Tests adhesive bonds in circuit boards, displays, and other electronic components.

- Medical and Biomedical Devices: Ensures reliable adhesion in medical products, including dressings, tapes, and implants.

- Textile and Apparel Industry: Evaluates adhesive bonds in fabrics and textiles used in garments and upholstery.

- Construction and Building Materials: Ensures the performance of adhesive bonds in construction materials like insulation films and flooring.

- Manufacturing and Consumer Goods: Widely used for testing adhesives in products ranging from packaging to household goods.

Peel Test Fixtures, when used with Universal Testing Machines (UTMs), provide accurate and reliable testing for adhesive strength and bonding properties across a wide range of materials. This makes them an essential tool for industries where adhesion plays a critical role in product quality and performance.