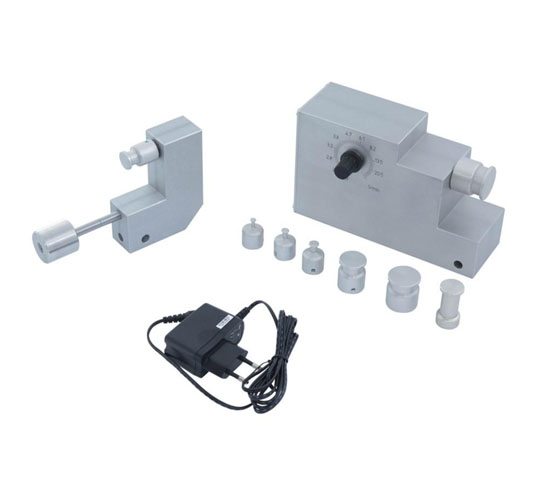

“O” Ring Grips: Universal Testing Machine Accessory for O-Ring Testing

The “O” Ring Grips are specialized grips designed for testing O-rings, offering precision and efficiency in material testing. With a motorized bottom fixture and a wide load capacity range, these grips are ideal for determining the performance and durability of O-rings in various applications.

- Load Capacity: Available with load capacities ranging from 100N to 5kN, suitable for testing O-rings of varying sizes and materials.

- Motorized Bottom Fixture: The motorized bottom fixture allows for controlled and repeatable testing of O-rings.

- O-Ring Compatibility: Designed to accommodate O-rings with diameters up to 100mm, providing flexibility for different test scenarios.

- Standards Compliance: Manufactured in accordance with ASTM D 1414, ensuring industry-standard performance and accuracy.

- Applications: Ideal for testing the mechanical properties and performance of O-rings used in sealing applications across multiple industries.