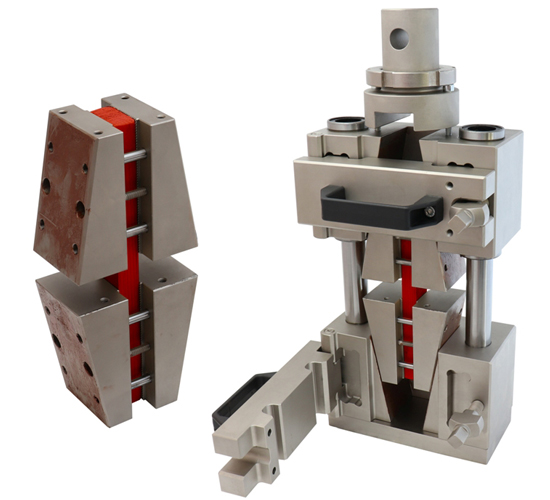

Compression Loading Fixture Applications

The Compression Loading Fixture is designed for testing materials under compressive stress to evaluate their strength, elasticity, hardness, and other critical properties. This fixture is widely used in mechanical testing with Universal Testing Machines (UTMs), particularly for evaluating materials that are subjected to compression forces. The fixture provides precise control over compression testing, ensuring that results are accurate and repeatable.

Applications for Universal Testing Machines (UTMs):

Compression Testing of Soft Materials: The Compression Loading Fixture is ideal for testing soft materials like foams, rubbers, and plastics. It helps assess their compressive strength, elasticity, and deformation properties under compressive loads. This is especially useful in the automotive, packaging, and construction industries, where materials often face compressive forces in their applications.

Concrete Testing: Compression Loading Fixtures are widely used in construction materials testing, particularly for concrete, cement, and bricks. They enable accurate measurement of the compressive strength of these materials, which is essential for ensuring the durability and stability of structures.

Metal Testing: These fixtures are also used for testing metal alloys and metallic materials under compressive loads. This is crucial for determining the yield strength, ductility, and stress-strain behavior of metals used in industries like aerospace, automotive, and manufacturing.

Rubber and Elastomer Testing: The Compression Loading Fixture is used to evaluate rubber, elastomers, and polymer materials in compression. The fixture helps determine how these materials behave when compressed, measuring their resilience, compression set, and hardness, which is critical in the automotive, medical, and industrial sectors.

Packaging Material Testing: Used in the packaging industry to test films, papers, and foils under compression. The fixture helps determine how materials perform under compressive forces, simulating how packaging materials behave during storage and transportation. It is used to assess tear resistance, strength, and compression performance.

Wood and Lumber Testing: Compression Loading Fixtures are essential in testing wood and lumber for compressive strength and resilience. These materials are tested for their performance under compression, which is crucial in the construction and furniture manufacturing industries.

Ceramic Material Testing: Used to evaluate the compressive strength of ceramic and porcelain materials. This is important for testing ceramic tiles, bricks, and glass products to ensure they can withstand compressive forces in real-world conditions.

Plastic and Polymer Testing: The fixture is used for testing plastic and polymer materials, including thermoplastics and thermosets. It helps determine their compression strength, yield points, and deformation properties under compressive loads, which is essential in industries such as packaging, automotive, and consumer goods.

Foam and Insulation Testing: Ideal for testing foams and insulation materials under compression, the fixture evaluates properties like compression set, density, and insulating performance. This is particularly important in construction and automotive industries, where foam and insulation are crucial for performance and energy efficiency.

Biomedical and Medical Device Testing: Compression Loading Fixtures are used to test materials used in medical devices, such as implants, prosthetics, and biomaterials. This helps assess their compressive strength and durability, ensuring that medical materials meet the required standards for patient safety.

Advantages of Compression Loading Fixture:

- Precise Compression Control: Provides controlled and consistent compression testing, crucial for accurate material analysis.

- Versatile: Suitable for a wide range of materials, from soft polymers to rigid metals, ensuring a broad application across industries.

- Durability: Built with high-quality materials that can withstand repeated compressive testing cycles without compromising performance.

- Ease of Use: Simple setup and operation make it ideal for labs and production environments requiring quick and reliable testing results.

- Adjustability: Adjustable for testing various specimen sizes and shapes, offering flexibility in testing a wide range of materials.

- Accurate Results: Provides reliable, reproducible test results that are critical for ensuring material performance and compliance with industry standards.

Industry Applications:

- Construction Industry: Used for testing materials like concrete, bricks, and cement for compressive strength, ensuring the stability and durability of buildings and structures.

- Automotive Industry: Applied in testing components like rubber seals, plastics, and metals to evaluate how they perform under compressive forces during vehicle production and testing.

- Packaging Industry: Essential in testing packaging materials like films and foils to ensure they can withstand compressive forces without damage, maintaining product integrity during storage and transport.

- Aerospace Industry: Used to test metal alloys and composite materials for strength under compressive loads, ensuring they meet safety and performance requirements for aircraft components.

- Biomedical Industry: Applied for testing biomaterials, medical implants, and prosthetics to determine their compressive properties and durability for patient safety.

- Consumer Goods: Used in testing plastics, rubbers, and elastomers for various applications, from electronics to household products.

The Compression Loading Fixture is an essential tool for testing materials under compressive stress. Its versatility, reliability, and precision make it a valuable asset for industries such as construction, automotive, aerospace, and biomedicine, ensuring accurate results and consistent material performance under compression.