LaVision: Digital Volume Correlation (DVC) Systems Overview

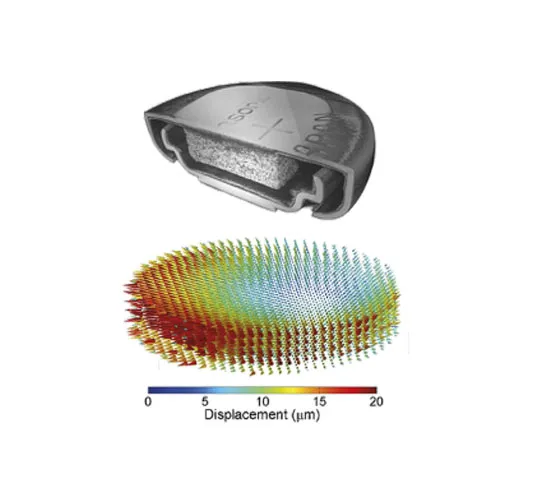

LaVision’s Digital Volume Correlation (DVC) Systems offer advanced 3D, non-contact analysis for the full-field measurement of displacements, strains, and deformations within three-dimensional volumes. DVC is an extension of traditional Digital Image Correlation (DIC), providing the ability to analyze complex 3D deformation behavior in materials and structures under load, making it an essential tool for various applications in materials science, mechanical engineering, and structural testing.

Full-Volume Deformation Measurement

- Unlike 2D or 3D DIC systems that only capture surface deformations, DVC systems measure internal and external deformations, offering detailed insights into the internal strain distribution within materials or structures.

High Precision and Accuracy

- The systems provide highly accurate measurements of 3D displacements and strain fields within a volume, with resolutions down to sub-micron levels. This precision is vital for critical applications, such as composite materials testing, fatigue analysis, and more.

Advanced 3D Imaging

- LaVision’s DVC systems use high-resolution 3D imaging techniques, typically combining multiple cameras or imaging setups, to capture volumetric data over a wide range of scales and from different perspectives.

Non-Contact Measurement

- As a non-contact measurement method, DVC allows for deformation analysis without physically interacting with the sample, preserving its integrity during testing.

In-Depth 3D Strain and Stress Analysis

- The system enables comprehensive analysis of not only displacements but also internal strain and stress distributions, including volumetric strain, shear strain, and more.

Flexible Application

- DVC systems can be used for a wide range of materials, including metals, polymers, composites, concrete, and biological tissues, among others.

User-Friendly Software

- LaVision’s software provides an intuitive interface for real-time data acquisition, visualization, and post-processing. It supports features like 3D visualization, automated calibration, and advanced strain mapping, making data analysis straightforward and efficient.

Adaptable to Various Testing Environments

- DVC systems can be employed in various environments, such as high-temperature testing, fatigue analysis, and dynamic load testing, offering versatility for different testing needs.