Specifications

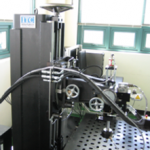

The Interlaken Technology Dent Test System provides the operator with the ability to evaluate the dent resistance of material specimens from something as simple as a 9″ “pie pan” type specimen to full body panels and even complete automobiles. This machine allows the operator to do static testing in completely automated fashion. A punch applies forces up to 1100 lbs., speeds up to 100 inches/second and a punch travel of 2″. A large work area of 10′ by 12′ enables the dent tester to accommodate full size automotive panels or sheet stock for testing.

The operation of the system consists of the following steps:

1. The indenter head is positioned manually to control the height, horizontal position and angle of rotation of the head.

2. Input parameters such as test speed, panel type, vehicle model, material ID, gauge, operator and project number are entered into the computer.

3. The operator tells the test to run.

4. The control software applies the appropriate loads and the appropriate speeds, incrementing the load and displacements. The software displays and records the appropriate data while the test is running.

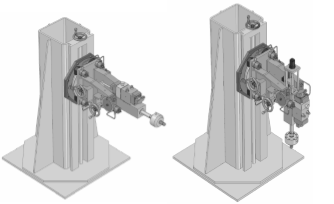

The system is available with a simple pedestal mount as shown at right. Indenter mechanism swivels and rotates to allow convenient positioning.