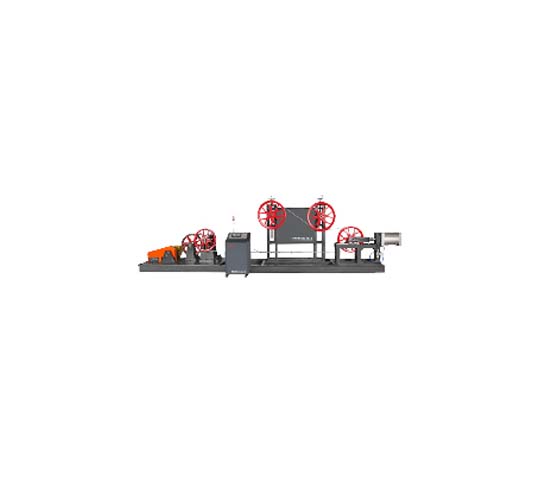

20kN Load Capacity Steel Wire Rope Fatigue Testing Machine Overview

The 20kN Load Capacity Steel Wire Rope Fatigue Testing Machine is a specialized testing system designed to evaluate the durability and fatigue performance of steel wire ropes under repeated stress cycles. With a robust design and high-precision testing capabilities, this machine ensures accurate and reliable results, making it indispensable for industries such as construction, mining, transportation, and manufacturing.

20kN Load Capacity

- Built to handle steel wire ropes with loads up to 20kN, accommodating a wide range of testing requirements for various rope diameters and materials.

Fatigue Testing Capabilities

- Performs high-cycle fatigue testing, simulating real-world conditions to assess the endurance and longevity of steel wire ropes under repeated load applications.

Advanced Load Control System

- Equipped with an intuitive and precise control system that allows for consistent load application and monitoring throughout the testing cycle.

Durable Construction

- Engineered with high-strength materials and components to ensure the machine’s longevity, even under continuous operation.

Customizable Test Parameters

- Supports customizable testing conditions, such as load amplitude, frequency, and cycle count, to meet specific testing standards or requirements.

Comprehensive Data Analysis

- Provides real-time monitoring and detailed data reporting, helping users analyze the fatigue behavior and performance of steel wire ropes effectively.