High Cycle Fatigue Testing

We have extensive experience across a wide range of industries

High Cycle Fatigue Testing

High Cycle Fatigue (HCF) Testing is used to evaluate a material’s ability to withstand repeated cyclic loading over a large number of cycles (typically 10⁴ to 10⁷ cycles) at relatively low stress levels. It is crucial for predicting the long-term durability of components in aerospace, automotive, defense, and structural applications.

Determines the fatigue life of a material under cyclic stresses.

Identifies the endurance limit (stress level below which a material can theoretically last indefinitely).

Helps in design optimization to prevent unexpected failures.

2. Test Methodology

Specimen Preparation: Machined to standard geometries such as dog-bone or hourglass shapes.

Gripping: Ensures proper alignment using threaded, collet, hydraulic, or wedge grips.

Loading Conditions:

Axial, bending, or torsional loading based on real-world applications.

Stress applied in a sinusoidal wave pattern (tension-tension, tension-compression, or fully reversed loading).

Test Execution:

The material is cyclically loaded at a constant stress amplitude until failure or until a pre-determined cycle limit is reached.

Failure mode analysis is conducted to examine fracture surfaces and fatigue crack propagation.

Material Type: Metals, polymers, composites, and ceramics have different fatigue behaviors.

Surface Finish: Rough surfaces introduce micro-cracks, reducing fatigue life.

Stress Ratio (R): Defined as R = min stress / max stress, affecting test results.

Frequency: Typically conducted at 10-100 Hz, depending on the material and machine capability.

Environmental Conditions: Temperature, humidity, and corrosive environments impact fatigue performance.

ASTM E466 – Conducting force-controlled fatigue tests of metallic materials.

ISO 1099 – Fatigue testing under axial force-controlled conditions.

ASTM D7774 – High cycle fatigue testing for polymers.

ISO 1143 – Rotating bending fatigue testing of metals.

High Cycle Fatigue (HCF) Testing – FAQs

1. What is High Cycle Fatigue (HCF) Testing?

High Cycle Fatigue (HCF) Testing evaluates a material’s ability to withstand cyclic loading over a high number of cycles (10⁴ to 10⁷) at relatively low stress levels. It helps determine the fatigue life and endurance limit of materials used in aerospace, automotive, and structural applications.

2. How is HCF testing different from Low Cycle Fatigue (LCF) testing?

- HCF Testing: High cycles (>10⁴), low stress, and elastic deformation.

- LCF Testing: Low cycles (<10⁴), high stress, and plastic deformation.

- HCF focuses on long-term durability, while LCF examines failure due to repeated high-stress loads.

3. What factors influence HCF test results?

- Material type and microstructure

- Surface finish (roughness can reduce fatigue life)

- Stress ratio (R = min stress / max stress)

- Frequency and loading type (axial, bending, torsional)

- Environmental conditions (temperature, humidity, corrosion)

4. What are the common failure modes in HCF testing?

HCF failures occur due to progressive crack growth from cyclic loading. The most common failure modes include:

- Fatigue Cracks (initiated at surface defects or stress concentrators)

- Microstructural Damage (phase changes, grain boundary failures)

- Fracture Surface Features (striations, beach marks indicating cyclic failure)

5. What standards are followed for HCF testing?

- ASTM E466 – Force-controlled fatigue testing of metals.

- ISO 1099 – Axial force-controlled fatigue testing.

- ASTM D7774 – Fatigue testing for polymers.

- ISO 1143 – Rotating bending fatigue testing of metals.

Looking for tensile testing services in India? Get accurate, NABL-certified material testing with advanced Universal Testing Machines (UTMs) today!

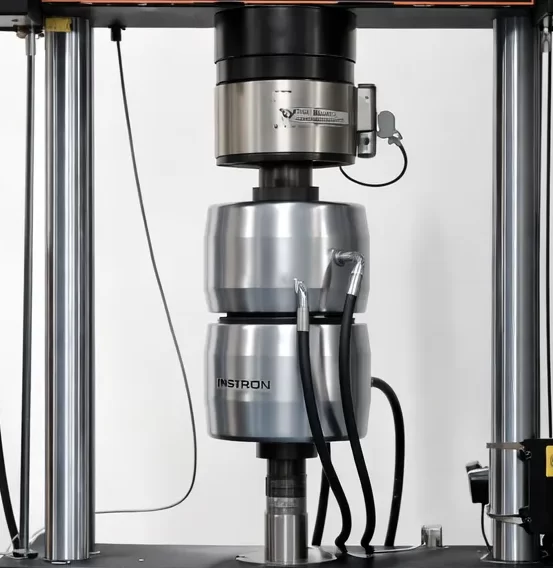

High Cycle Fatigue (HCF) Testing Gripping

Gripping is a critical aspect of High Cycle Fatigue (HCF) testing, ensuring accurate load application without introducing unwanted stresses. Proper gripping techniques prevent slippage, misalignment, and premature failure due to stress concentrations at the grip section.

Types of Gripping Methods in HCF Testing

1. Threaded Grips

Used for cylindrical specimens with threaded ends.

Provides secure clamping without excessive stress at the grip section.

Common in metallic material testing (ASTM E466, ISO 1099).

2. Collet Grips

Ideal for round specimens with smooth ends.

Ensures uniform load distribution, reducing stress concentration.

Used in high-precision fatigue testing applications.

3. Hydraulic Grips

Applies consistent gripping force using hydraulic pressure.

Prevents specimen damage by adjusting clamping pressure dynamically.

Preferred for high-frequency and high-load fatigue testing.

4. Wedge Grips

Used for flat and rectangular specimens.

Self-tightening mechanism helps prevent slippage.

Common in composite and polymer fatigue testing.

5. Pin-Loaded Grips

Utilized for sheet metal and thin materials.

Reduces stress concentrations by allowing slight movement at the grip points.

Often used in aircraft structural fatigue tests.

High Cycle Fatigue (HCF) Testing Gripping – FAQs

1. Why is proper gripping important in High Cycle Fatigue (HCF) testing?

Proper gripping ensures accurate load application, prevents specimen slippage, and eliminates unwanted stress concentrations at the grip section. Poor gripping can lead to premature failure, affecting test accuracy.

2. What are the common types of grips used in HCF testing?

- Threaded Grips – Secure cylindrical specimens with threaded ends.

- Collet Grips – Provide uniform clamping for smooth round specimens.

- Hydraulic Grips – Maintain consistent grip force without damaging the sample.

- Wedge Grips – Self-tightening grips for flat specimens.

- Pin-Loaded Grips – Reduce stress concentration in thin materials.

3. How does misalignment affect fatigue test results?

Misalignment can cause bending stresses, leading to inaccurate fatigue life predictions. Properly aligned specimens ensure that the applied load is purely axial, as required in HCF testing.

4. How can gripping-induced stress be minimized?

- Using polished and precision-machined specimen ends to prevent stress risers.

- Employing soft jaw inserts or coatings to reduce surface damage.

- Ensuring even grip pressure to avoid localized stress concentrations.

5. What standards guide gripping methods in HCF testing?

- ASTM E466 – Standard practice for force-controlled fatigue testing of metals.

- ISO 1099 – Fatigue testing of metals under axial force-controlled conditions.

- ASTM D7774 – High cycle fatigue testing for polymers.

Looking for tensile testing services in India? Get accurate, NABL-Certified material testing with advanced Universal Testing Machines (UTMs) today!

High Cycle Fatigue (HCF) Testing Sample Preparation

High Cycle Fatigue (HCF) Testing evaluates a material’s ability to withstand cyclic loading for a large number of cycles (typically 10⁴ to 10⁷ cycles) at relatively low stress levels. Proper sample preparation is crucial to ensure accurate and repeatable test results.

1. Specimen Selection and Machining

Material Choice: The specimen is extracted from the desired material, ensuring it represents real-world conditions.

Precision Machining: The specimen is machined to exact dimensions as per ASTM E466 (metals) or ISO 1099 standards.

Shape Considerations: 0.1: Typically, specimens have a dog-bone or hourglass shape to ensure uniform stress distribution.

0.2: Avoid sharp edges or sudden cross-section changes to prevent stress concentration.

2. Surface Finishing and Polishing

Surface roughness significantly affects fatigue life; therefore, samples undergo:

Grinding and polishing to remove machining marks.

Electropolishing (if required) to achieve a mirror-like finish, especially for aerospace or biomedical applications.

3. Specimen Alignment and Gripping

Proper alignment is crucial to prevent unintended bending stresses.

Threaded or smooth grips are used, depending on the test setup.

Special coatings or lubrication may be applied to reduce gripping damage.

4. Pre-Test Inspection

Dimensional Verification: Ensures the sample meets standard requirements.

Surface Quality Check: Examines for cracks, inclusions, or irregularities.

Hardness Testing (if required): Confirms uniform material properties.

High Cycle Fatigue (HCF) Testing Sample Preparation – FAQs

1. Why is precise sample preparation important for High Cycle Fatigue Testing?

Proper sample preparation ensures accurate and repeatable results by minimizing surface defects, residual stresses, and misalignment. Any imperfections can lead to premature failure, affecting fatigue life predictions.

2. What are the standard shapes for HCF test specimens?

The most common specimen geometries include:

- Dog-bone (ASTM E466) – Provides uniform stress distribution.

- Hourglass shape – Reduces stress concentration at grip sections.

- Flat or cylindrical samples – Used depending on material and industry standards.

3. How does surface finish affect fatigue test results?

A rough surface can introduce micro-cracks that significantly reduce fatigue life. To prevent this:

- Grinding and polishing are performed to remove machining marks.

- Electropolishing is sometimes used for a mirror-like finish, particularly in aerospace applications.

4. What factors influence specimen gripping for fatigue testing?

Proper gripping is essential to avoid additional stresses. Common grip types include:

- Threaded grips – Minimize slippage and damage.

- Smooth grips with end tabs – Used for thin or soft materials.

- Collet grips – Ensure uniform load distribution and alignment.

5. What standards are followed for HCF sample preparation?

High Cycle Fatigue Testing follows international standards such as:

- ASTM E466 – Conducting force-controlled fatigue tests on metallic materials.

- ISO 1099 – Fatigue testing of metals under axial force-controlled conditions.

- ASTM D7774 – High Cycle Fatigue testing for polymers.

By following these guidelines, industries ensure reliable fatigue data for aerospace, automotive, and structural material applications.

Looking for High Cycle Fatigue (HCF) Testing services in India? Get accurate, NABL-certified material testing with advanced Universal Testing Machines (UTMs) today!

Registration & Certifications

We are a certified and registered organization committed to quality and compliance.

Accredited by NABL

(National Accreditation Board for Testing and Calibration Laboratories – India)

Our laboratory is accredited by NABL as it meets international standards for quality and competence.

It operates in accordance with ISO/IEC 17025:2017. NABL accreditation is recognized

both nationally and internationally.

If you are looking for NABL-accredited testing laboratories in India, our facility provides high-precision testing services in compliance with global quality standards

- Tensile Testing: ASTM E8M, ASTM E21, ASTM B557M, ASTM A770, ASTM D3039M, ASTM D412, ASTM D638, IS 1608 (Part-1, Part-3), ISO 6892

- Compression Testing: ASTM D575

- Bend Testing: ASTM E290, IS 1599

- Low Cycle Fatigue Testing: ASTM E606

- High Cycle Fatigue Testing: ASTM E466

- Fatigue Crack Growth Rate Testing: ASTM E647

- Fracture Toughness Testing (KIC): ASTM E399

- Fracture Toughness Testing (JIC): ASTM E1820

- Creep & Stress Rupture Testing: ASTM E139, ASTM E292

AS9100:2016 Certified

MIC Labs is certified by IAS in accordance with AS9100:2016, meeting international aerospace quality standards.

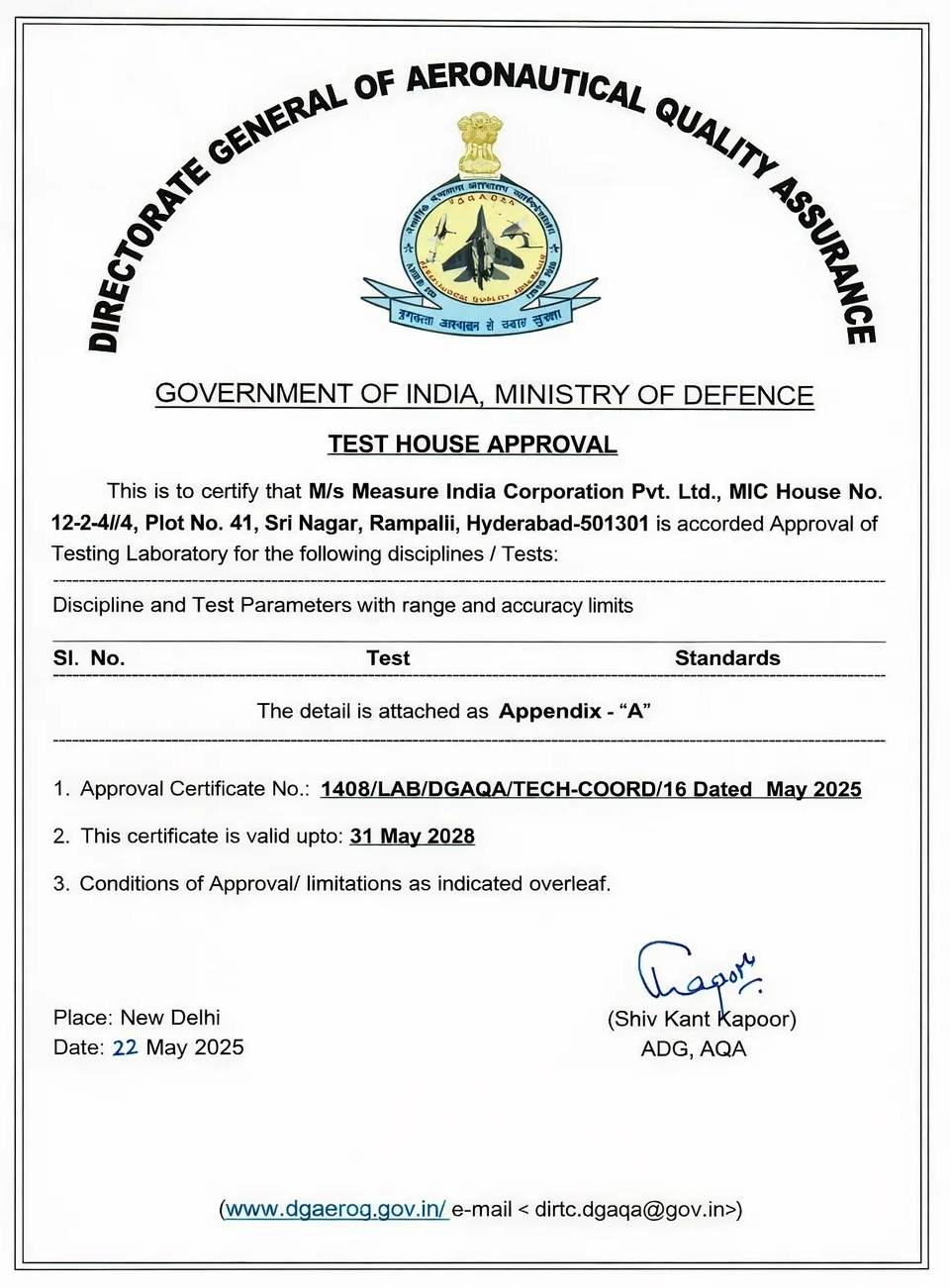

Approved by DGAQA

MIC Labs is approved by DGAQA, ensuring compliance with aerospace and defense testing requirements.

Registered by UDYAM

Measure India Corporation Pvt Ltd is UDYAM registered, recognizing us as a certified MSME in India.

This registration highlights our commitment to quality, statutory compliance, and industry standards.

Why Choose Us

We have 20 years of experience in providing material testing systems and offering testing services with great confidence.

- 90+ Products

- 500+ Customers

- 35+ Team Size

- Expertise in guiding and working with top-notch researchers and engineers

- World-class mechanical testing laboratory

Mechanical Testing Lab Services & Universal Testing Machines Suppliers in India

“With over 20 years of experience, Measure India Corporation Pvt Ltd supplies Universal Testing Machines & mechanical testing services, ensuring precision, reliability, and compliance with ASTM, ISO, and global standards across various industries.”

Contact Information

9:00 AM – 5:30 PM

Sreenagar, Rampally,

Hyderabad, Telangana 501301

Get In Touch With Us

Please fill out the form below and a member of our team will respond promptly.