Fracture Toughness Testing

We have extensive experience across a wide range of industries

How Fracture Toughness Testing Works – Process & Importance

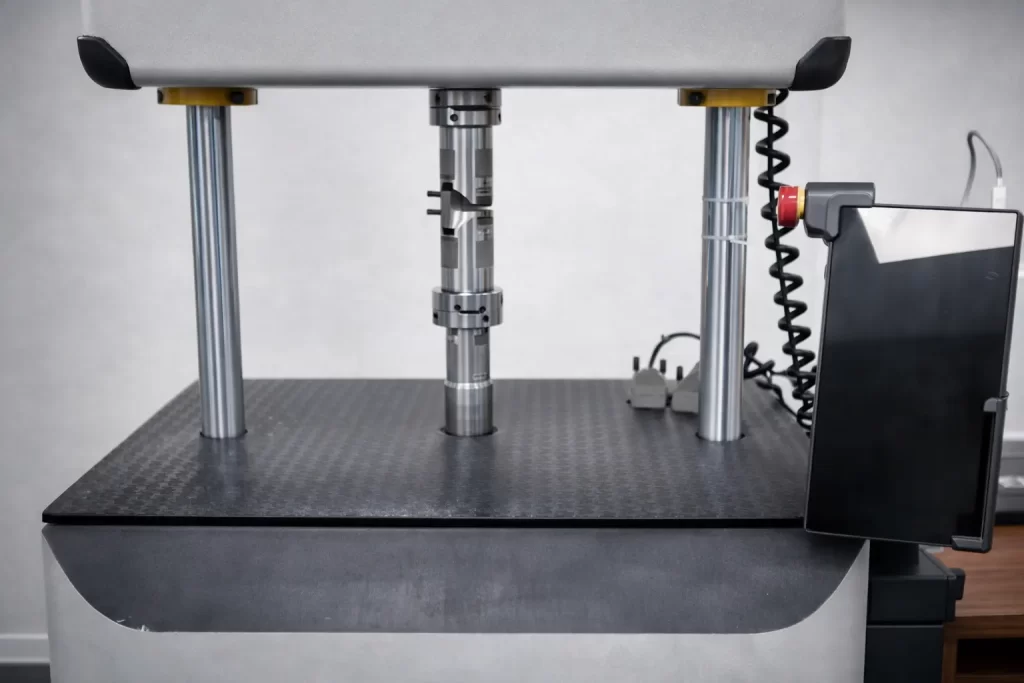

MIC Labs is equipped to test various materials under tensile loading, meeting the following standard.

Fracture Toughness Testing – Standard Test Methods

Fracture toughness testing evaluates a material’s ability to resist crack propagation under applied stress. It is critical for ensuring the reliability and safety of materials used in aerospace, automotive, defense, and structural applications. The following international standards define the methodologies for fracture toughness evaluation across different materials:

ASTM E399 – Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness (K1c) of Metallic Materials

- Applicable for metallic materials exhibiting linear-elastic behavior.

- Determines K1c (plane-strain fracture toughness), a key parameter for brittle fracture resistance.

- Uses Compact Tension (C(T)) or Single Edge Notched Bend (SENB) specimens.

ASTM E1820 – Standard Test Method for Measurement of Fracture Toughness

- Covers multiple fracture toughness parameters, including J1c (J-integral) and K1c.

- Suitable for both ductile and brittle materials.

- Incorporates methods for crack growth resistance curves (R-curves).

ISO 12135 – Metallic Materials – Determination of Fracture Toughness

- Equivalent to ASTM E1820, providing a comprehensive approach to fracture toughness testing.

- Evaluates K1c, J1c, and CTOD (Crack Tip Opening Displacement).

- Defines requirements for specimen preparation, pre-cracking, and test execution.

BS 7448 – Fracture Mechanics Toughness Tests

- British standard widely used for structural integrity assessments.

- Includes methodologies for measuring K1c, J1c, and CTOD.

- Applied to welded joints and structural components.

ASTM D5045 – Standard Test Methods for Plane-Strain Fracture Toughness of Plastics

- Used for rigid plastics and polymer composites.

- Determines K1c and G1c (fracture energy release rate).

- Uses single-edge notch bending (SENB) specimens with controlled pre-cracking.

ISO 13586 – Plastics – Determination of Fracture Toughness (G1c and K1c)

- Equivalent to ASTM D5045, covering plastics and polymer-based materials.

- Provides guidelines for specimen preparation, crack initiation, and toughness evaluation.

At MIC Labs, we adhere to these international standards, utilizing state-of-the-art equipment and precision specimen preparation to deliver accurate and reliable fracture toughness testing for various industries.

Fracture Toughness Testing – FAQs

1. What is fracture toughness testing?

Fracture toughness testing measures a material's resistance to crack propagation under applied stress. It helps assess the structural integrity of materials used in critical applications like aerospace, automotive, and construction.

2. What are the common fracture toughness testing methods?

The most widely used methods include:

- KIC Testing (Linear Elastic Fracture Mechanics - LEFM)

- J-Integral Testing (Elastic-Plastic Fracture Mechanics)

- CTOD (Crack Tip Opening Displacement) Testing

3. Which materials require fracture toughness testing?

Metals, composites, ceramics, polymers, and advanced materials used in load-bearing or high-stress environments require fracture toughness testing to ensure durability and safety.

4. What is the standard specimen geometry for fracture toughness testing?

The most commonly used specimen types include:

- Single Edge Notch Bend (SENB)

- Compact Tension (CT)

- Disc-Shaped Compact Tension (DCT)

5. Which standards govern fracture toughness testing?

Common international standards include:

- ASTM E399 (Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness)

- ASTM E1820 (J-Integral and CTOD Testing)

- ISO 12135 (Fracture Toughness of Metallic Materials)

Looking for Fracture testing services in India? Get accurate, NABL-certified material testing with advanced Universal Testing Machines (UTMs) today!

Fracture Toughness Testing – Gripping

Proper gripping is essential in fracture toughness testing to ensure accurate and repeatable results. MIC Labs utilizes specialized fixturing techniques to securely hold specimens while applying controlled loads. The gripping method depends on the specimen type and the testing standard being followed.

Common Gripping Methods:

Pinned Grips (for Compact Tension C(T) Specimens):

Uses precision-machined holes to accommodate loading pins.

Ensures uniform force distribution without introducing bending stresses.

Three-Point & Four-Point Bending Fixtures (for SENB Specimens):

Supports the specimen on rollers while applying a controlled load at the notch.

Commonly used for brittle materials and high-strength alloys.

Wedge Grips (for SENT Specimens):

Holds single-edge notched tension specimens securely while preventing misalignment.

Used in fracture mechanics studies for pipelines and ductile materials.

At MIC Labs, our advanced gripping fixtures are designed to minimize stress concentrations, misalignment, and unintended loading effects, ensuring precise fracture toughness evaluations across various industries.

Fatigue Testing Gripping – FAQs

1. How do you prevent specimen slippage during fatigue testing?

Specimen slippage can lead to inaccurate test results and premature failure. To prevent this:

Use serrated or textured grip surfaces for better friction.

Apply precise gripping force to avoid crushing or damaging the specimen.

Ensure proper alignment to minimize bending stresses and uneven loading.

2. What types of grips are best for fatigue testing?

The best grip type depends on the material and test requirements. Common options include:

Hydraulic Grips – Ideal for high-load fatigue testing due to consistent clamping force.

Wedge Grips – Self-tightening under load, preventing slippage.

Threaded Grips – Best for round specimens, ensuring strong axial alignment.

Pin-Loaded Grips – Used in fracture mechanics fatigue tests like Compact Tension (C(T)) specimens.

3. Why is proper gripping important in fatigue testing?

Uniform load distribution, reducing stress concentrations.

Minimized misalignment, preventing bending stresses.

Consistent and repeatable results, which is critical for material performance evaluations.

4. What are the challenges of gripping different materials in fatigue testing?

Metals: Need high-strength grips to handle cyclic loads.

Polymers & Composites: Require softer gripping surfaces to prevent local damage.

Thin Sheets & Wires: Need custom grips to avoid deformation and ensure secure clamping.

5. How does MIC Labs ensure accurate gripping in fatigue testing?

MIC Labs uses:

Advanced gripping solutions with adjustable clamping forces.

Precision alignment mechanisms to reduce test variability.

Material-specific grips for metals, polymers, and composite materials.

These techniques ensure reliable fatigue life assessments for industries like aerospace, automotive, and manufacturing.

Looking for tensile testing services in India? Get accurate, NABL-Certified material testing with advanced Universal Testing Machines (UTMs) today!

How Fracture Toughness Testing Works – Process & Importance

Fracture toughness testing requires precisely machined specimens to evaluate a material’s resistance to crack propagation under applied stress. At MIC Labs, our dedicated sample preparation workshop ensures that test specimens meet the stringent requirements of ASTM E399 (Linear-Elastic Plane-Strain Fracture Toughness), ASTM E1820 (Elastic-Plastic Fracture Toughness), and ISO 12135 standards.

Common fracture toughness specimen types include:

Compact Tension (C(T)) – Ideal for metals and composites

Single Edge Notched Bend (SENB) – Suitable for brittle materials

Single Edge Notched Tension (SENT) – Used for pipeline materials

Chevron Notched Specimen – Evaluates fracture toughness under controlled crack growth

Fracture Toughness Testing – FAQs

1. Why is fracture toughness testing important?

Fracture toughness testing determines a material’s ability to resist crack growth under applied stress. It is critical for industries like aerospace, defense, and manufacturing, where structural integrity and failure prevention are essential. The test helps in:

Evaluating material durability under extreme conditions.

Predicting failure risks in components.

Ensuring compliance with international standards like ASTM E399, ASTM E1820, and ISO 12135.

2. What are the common specimen types used in fracture toughness testing?

Different specimen types are used based on material properties and testing requirements:

Compact Tension (C(T)) – Ideal for metals and composites.

Single Edge Notched Bend (SENB) – Used for brittle materials.

Single Edge Notched Tension (SENT) – Preferred for ductile and pipeline materials.

Chevron Notched Specimen – Evaluates fracture toughness with controlled crack growth.

3. How is gripping handled in fracture toughness testing?

Proper gripping ensures accurate load application and prevents misalignment. Common methods include:

Pinned Grips (C(T) Specimens) – Uses loading pins to distribute force evenly.

Three-Point & Four-Point Bending Fixtures (SENB Specimens) – Provides stable loading conditions.

Wedge Grips (SENT Specimens) – Prevents slippage and ensures axial alignment.

4. What are the key factors affecting fracture toughness test results?

Specimen Preparation: Precision in machining and pre-cracking ensures reliable results.

Loading Rate: Must follow test standards to avoid dynamic effects.

Temperature Conditions: Testing at extreme temperatures simulates real-world applications.

Crack Initiation & Growth Monitoring: Helps in accurate measurement of fracture toughness.

5. How does MIC Labs ensure reliable fracture toughness testing?

MIC Labs maintains state-of-the-art machining centers and precision-controlled testing environments to ensure:

High-accuracy specimen preparation with tight tolerances.

Advanced gripping techniques for stable and repeatable tests.

Strict adherence to global standards for aerospace, automotive, and manufacturing industries.

These measures ensure dependable fracture toughness evaluations for critical applications.

6. which is the Best Lab for Fracture Toughness Testing in Hyderabad, India?

MIC Labs is a leading provider of Fracture Toughness Testing in Hyderabad, India, adhering to international standards such as ASTM E399, ASTM E1820, ISO 12135, and BS 7448. Our advanced testing facility is equipped with state-of-the-art machining centers and precision specimen preparation to ensure accurate and repeatable results.

We serve clients across major cities in India, including Hyderabad, Bengaluru, Chennai, Mumbai, Pune, Delhi, Ahmedabad, Kolkata, and Coimbatore, catering to industries such as aerospace, automotive, defense, manufacturing, construction, energy, biomedical, and research & development.

For expert fracture toughness testing services, contact MIC Labs today!

Looking for Fatigue testing services in India? Get accurate, NABL-certified material testing with advanced Universal Testing Machines (UTMs) today!

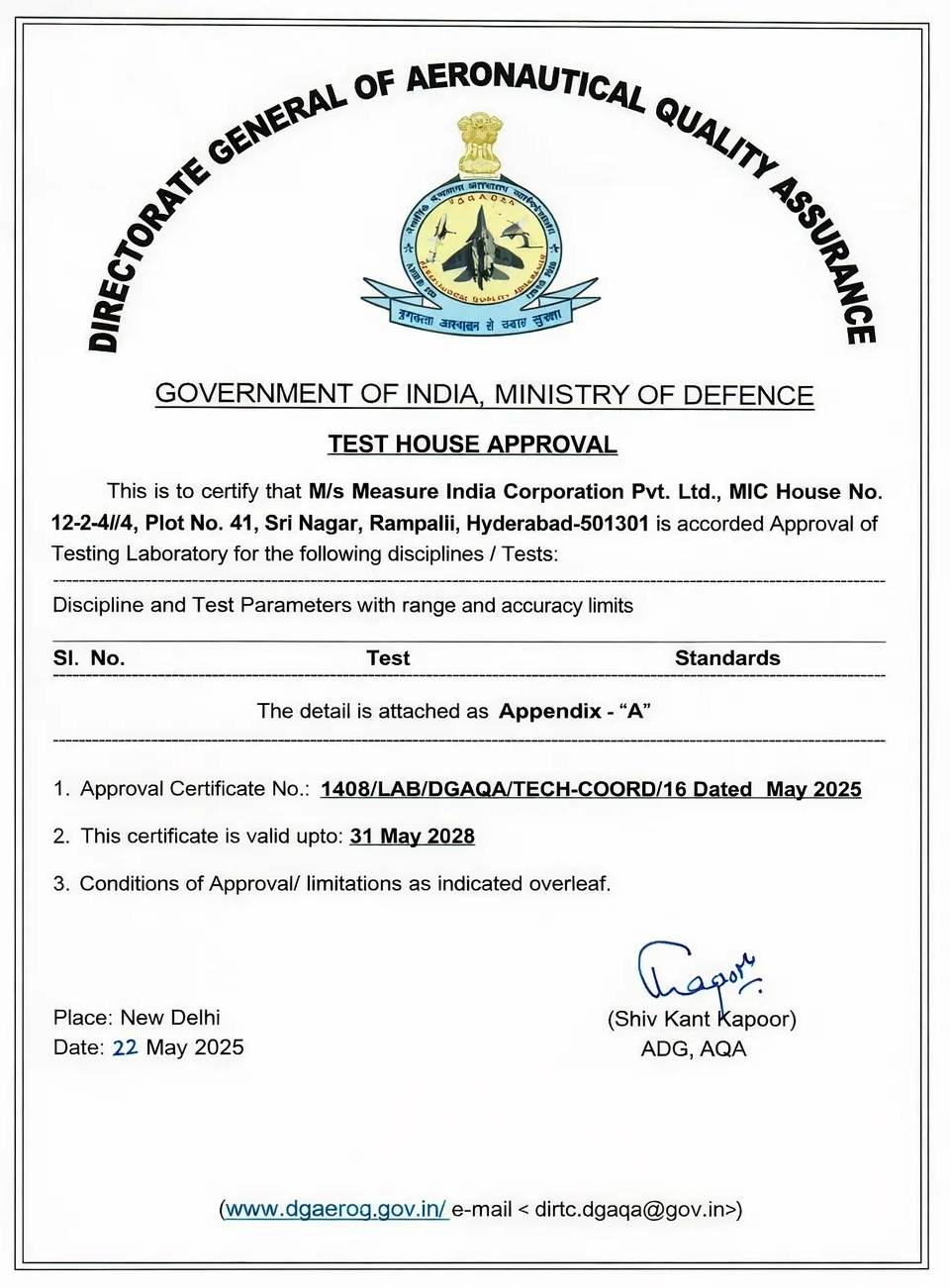

Registration & Certifications

We are a certified and registered organization committed to quality and compliance.

Accredited by NABL

(National Accreditation Board for Testing and Calibration Laboratories – India)

Our laboratory is accredited by NABL as it meets international standards for quality and competence.

It operates in accordance with ISO/IEC 17025:2017. NABL accreditation is recognized

both nationally and internationally.

If you are looking for NABL-accredited testing laboratories in India, our facility provides high-precision testing services in compliance with global quality standards

- Tensile Testing: ASTM E8M, ASTM E21, ASTM B557M, ASTM A770, ASTM D3039M, ASTM D412, ASTM D638, IS 1608 (Part-1, Part-3), ISO 6892

- Compression Testing: ASTM D575

- Bend Testing: ASTM E290, IS 1599

- Low Cycle Fatigue Testing: ASTM E606

- High Cycle Fatigue Testing: ASTM E466

- Fatigue Crack Growth Rate Testing: ASTM E647

- Fracture Toughness Testing (KIC): ASTM E399

- Fracture Toughness Testing (JIC): ASTM E1820

- Creep & Stress Rupture Testing: ASTM E139, ASTM E292

AS9100:2016 Certified

MIC Labs is certified by IAS in accordance with AS9100:2016, meeting international aerospace quality standards.

Approved by DGAQA

MIC Labs is approved by DGAQA, ensuring compliance with aerospace and defense testing requirements.

Registered by UDYAM

Measure India Corporation Pvt Ltd is UDYAM registered, recognizing us as a certified MSME in India.

This registration highlights our commitment to quality, statutory compliance, and industry standards.

Why Choose Us

We have 20 years of experience in providing material testing systems and offering testing services with great confidence.

- 90+ Products

- 500+ Customers

- 35+ Team Size

- Expertise in guiding and working with top-notch researchers and engineers

- World-class mechanical testing laboratory

Mechanical Testing Lab Services & Universal Testing Machines Suppliers in India

“With over 20 years of experience, Measure India Corporation Pvt Ltd supplies Universal Testing Machines & mechanical testing services, ensuring precision, reliability, and compliance with ASTM, ISO, and global standards across various industries.”

Contact Information

9:00 AM – 5:30 PM

Sreenagar, Rampally,

Hyderabad, Telangana 501301

Get In Touch With Us

Please fill out the form below and a member of our team will respond promptly.