Fatigue Crack Growth Testing

We have extensive experience across a wide range of industries

How Fatigue Crack Growth (FCG) Testing Works – Process & Importance

Fatigue Crack Growth (FCG) Testing is a crucial method for evaluating how cracks propagate in materials under repeated cyclic loading. It helps industries assess the durability, structural integrity, and fatigue life of materials used in critical applications such as aerospace, automotive, defense, and construction.

Process of Fatigue Crack Growth Testing

Specimen Preparation

- Standardized specimens such as Compact Tension (CT), Middle Tension (MT), or Single Edge Notch Bend (SENB) are used.

- A small pre-crack is introduced to simulate real-world fatigue conditions.

Gripping & Fixture Setup

- The specimen is securely gripped using clevis grips (for CT specimens), hydraulic grips, or bend fixtures to ensure uniform loading.

- Proper alignment prevents secondary stresses that could affect crack growth measurements.

Pre-Cracking Stage

- Cyclic loading is applied at controlled force levels to grow the initial crack to a specified length before actual testing.

- This ensures a natural fatigue crack rather than an artificially induced one.

Fatigue Testing Under Cyclic Loading

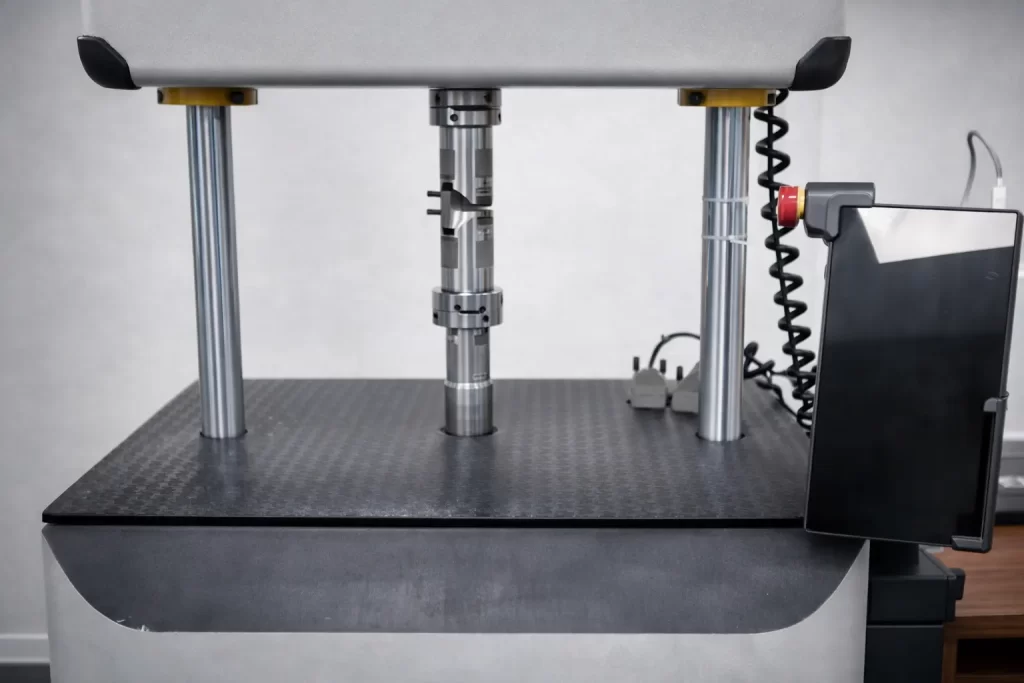

- The specimen undergoes tensile-compression cyclic loading using a servo-hydraulic or electromechanical testing machine.

- Crack propagation is monitored using optical microscopy, Digital Image Correlation (DIC), or compliance techniques.

Crack Growth Measurement

- Crack length is recorded at different cycles to determine the fatigue crack growth rate (da/dN) versus the stress intensity factor range (∆K).

- The Paris Law equation is commonly used to predict fatigue life.

Data Analysis & Failure Prediction

- The collected data helps engineers predict the remaining life of a material/component.

- Used to modify designs, select materials, or implement preventive maintenance strategies.

Importance of Fatigue Crack Growth Testing

Predicts Component Lifespan

- Helps determine how long a material can withstand repeated loading before failure.

Enhances Material Selection & Design

- Assists in choosing fatigue-resistant materials for critical applications.

Ensures Safety in Aerospace & Automotive Applications

- Prevents catastrophic failures in aircraft structures, bridges, vehicle chassis, and industrial machinery.

Improves Structural Integrity & Performance

- Provides insights into how cracks initiate and propagate, allowing for better material processing and manufacturing.

Reduces Maintenance Costs & Increases Reliability

- Prevents unexpected failures, leading to cost savings in repairs, downtime, and replacements.

By conducting Fatigue Crack Growth Testing, industries can develop safer, more reliable, and longer-lasting materials and structures.

Fatigue Crack Growth Testing – FAQs

1. What is Fatigue Crack Growth (FCG) Testing?

FCG testing evaluates how cracks propagate in materials under repeated cyclic loading. It helps determine fatigue life, structural integrity, and failure resistance in applications like aerospace, automotive, and construction.

2. What are the common specimen types used in FCG testing?

Standard specimens include:

- Compact Tension (CT) – Common for metals and alloys.

- Middle Tension (MT) – Used for thin sheet materials.

- Single Edge Notch Bend (SENB) – Ideal for fracture toughness studies.

3. What factors affect fatigue crack growth rate?

The crack growth rate depends on:

- Stress intensity factor range (∆K) – Higher values lead to faster crack propagation.

- Material properties – Some materials resist fatigue better than others.

- Load frequency & amplitude – More frequent or higher loads accelerate crack growth.

- Environmental conditions – Corrosion, temperature, and humidity can influence crack behavior.

4. How is crack growth measured during FCG testing?

Crack propagation is monitored using:

- Optical measurement (microscopy, Digital Image Correlation - DIC)

- Compliance method (change in specimen stiffness)

- Potential drop method (electrical resistance changes as crack grows)

5. What standards govern FCG testing?

FCG testing follows industry standards like:

- ASTM E647 – Standard for measuring fatigue crack growth rates.

- ISO 12108 – International guideline for FCG testing.

- ASTM E1820 – Fracture toughness testing, including FCG considerations.

FCG testing is essential for predicting failure risks, optimizing material selection, and improving structural durability across industries.

Looking for Fatigue Crack Growth Testing Services in India? Get accurate, NABL-certified material testing with advanced Universal Testing Machines (UTMs) today!

Fatigue Crack Growth (FCG) Gripping – Process & Importance

Fatigue Crack Growth (FCG) testing requires precise gripping techniques to ensure accurate loading, minimize misalignment, and achieve reliable crack growth measurements. The gripping method directly impacts test repeatability and the validity of results.

Gripping Process in Fatigue Crack Growth Testing

Specimen Selection & Preparation:

Standardized specimens like Compact Tension (CT) or Middle Tension (MT) are used.

The specimen ends are machined with precise holes or grip surfaces for proper attachment.

Fixture & Grip Design:

Clevis Grips: Used for CT specimens, with pins inserted through holes for uniform load distribution.

Wedge Grips or Hydraulic Grips: Used for MT specimens to maintain firm axial alignment under cyclic loads.

Three-Point & Four-Point Bend Fixtures: Used for Single Edge Notch Bend (SENB) specimens in fracture toughness tests.

Alignment & Load Application: Misalignment can cause uneven stress distribution, leading to incorrect crack propagation data.

High-precision fixtures ensure the loading axis passes through the specimen’s centerline.

Testing Under Controlled Conditions: The specimen undergoes cyclic loading in a servo-hydraulic fatigue testing machine.

Crack growth is monitored using Digital Image Correlation (DIC), compliance methods, or direct imaging techniques.

Importance of Proper Gripping in FCG Testing

Accurate Crack Growth Measurement: Proper gripping ensures even stress distribution, leading to reliable fatigue life predictions.

Prevention of Secondary Bending & Misalignment: Incorrect gripping can introduce unwanted bending stresses, affecting crack propagation behavior.

Enhanced Repeatability & Test Validity: Standardized grips help maintain uniform test conditions, ensuring compliance with ASTM E647 & ISO 12108.

Minimization of Specimen Slippage & Failure: Secure gripping prevents premature failure outside the intended crack region.

Ensuring Industry Compliance & Safety: Proper gripping techniques contribute to aerospace, automotive, and structural safety, where fatigue crack growth assessment is crucial.

By using the correct gripping method, engineers can achieve accurate, repeatable, and industry-standard fatigue crack growth test results, leading to better material design and failure prevention.

Fatigue Crack Growth (FCG) Gripping – FAQs

1. What type of grips are commonly used for Fatigue Crack Growth (FCG) testing?

FCG testing uses different grips based on specimen type:

- Clevis Grips (Pin Loading): Used for Compact Tension (CT) specimens to ensure uniform load distribution.

- Hydraulic or Wedge Grips: Suitable for Middle Tension (MT) specimens to provide firm axial alignment.

- Three-Point & Four-Point Bend Fixtures: Used for Single Edge Notch Bend (SENB) specimens in fracture toughness studies.

2. How does improper gripping affect FCG test results?

Misalignment, excessive clamping force, or slippage can introduce secondary bending stresses or uneven load distribution, leading to inaccurate crack propagation rates and invalid test results.

3. What factors influence the choice of grips in FCG testing?

The grip selection depends on:

- Specimen geometry (CT, MT, SENB, round, or flat).

- Material type (metals, composites, polymers, ceramics).

- Load and cyclic fatigue conditions.

- Surface finish (to prevent damage or stress concentration).

4. How can slippage be prevented during FCG testing?

- Use serrated grips or coatings for polished materials.

- Ensure proper specimen alignment to avoid asymmetric loading.

- Use hydraulic or mechanical tightening to maintain consistent gripping force.

5. What standards guide FCG gripping techniques?

- ASTM E647 – Standard Test Method for Measurement of Fatigue Crack Growth Rates.

- ISO 12108 – International standard for FCG testing.

- ASTM E1820 – Guidelines for fracture toughness testing, including gripping considerations.

Proper gripping techniques ensure repeatability, accuracy, and compliance with industry standards, making FCG testing more reliable for material durability and fatigue life assessment.

Looking for tensile testing services in India? Get accurate, NABL-Certified material testing with advanced Universal Testing Machines (UTMs) today!

Fatigue Crack Growth (FCG) Sample – Process & Importance

At MIC Labs, maintaining a well-structured quality sample preparation plays a key role in generating accurate and repeatable test data. Keeping this in view, MIC Labs initiated the establishment of its own sample preparation workshop in 2023. Over time, we have developed a state-of-the-art machining center to extract, prepare, and polish test specimens according to various ASTM, ISO, and IS testing standards.

Our experienced machinists are highly skilled in preparing specimens with tight tolerances, meeting the stringent requirements of the aerospace, defense, and manufacturing industries, as well as crucial research projects and academic programs.

The in-house workshop has also enabled MIC Labs to undertake high-volume testing contracts while ensuring quality and timely deliverables. With advanced machining capabilities, we ensure precision, consistency, and compliance with global testing standards, strengthening our position as a trusted partner in material testing and validation.

Fatigue Crack Growth (FCG) Testing Process – Sample Preparation

A standardized specimen is prepared according to global testing standards like ASTM E647 (for fatigue crack growth rate measurement) and ISO 12108 (for metallic materials under cyclic loading). The sample types commonly used in FCG testing include:

✔ Compact Tension (CT) Specimen – Preferred for metals, alloys, and aerospace materials.

✔ Middle Tension (MT) Specimen – Suitable for sheet materials and thin plates.

✔ Single Edge Notch Bend (SENB) Specimen – Used for fracture mechanics and toughness evaluation.

✔ Crack-Line Wedge-Loaded (CWL) Specimen – Designed for specific fatigue applications.

Precision in sample machining, surface finish, and alignment is crucial to ensure accurate crack growth measurements, prevent secondary stresses, and maintain repeatability in test results. Proper pre-cracking and notching techniques help establish a natural fatigue crack for reliable data analysis.

Fatigue Crack Growth (FCG) Testing Sample Preparation: FAQs

1. What type of material samples are used for Fatigue Crack Growth (FCG) testing?

Fatigue crack growth testing is typically performed on metallic alloys, composites, and advanced materials used in aerospace, automotive, and structural applications. Standardized specimen types include Compact Tension (CT) and Middle Tension (MT) samples.

2. How is the initial pre-crack introduced in the sample?

The pre-crack is introduced using cyclic loading in a servo-hydraulic or electromechanical testing machine. The loading follows ASTM E647 or ISO 12108 standards to ensure a natural crack initiation without excessive plastic deformation.

3. What are the common dimensions and standards for FCG test specimens?

Standardized dimensions follow ASTM E647 and vary based on material thickness and application. Common specimen types include:

- Compact Tension (CT): Widely used in research and industry.

- Middle Tension (MT): Preferred for sheet materials.

- Single Edge Notch Bend (SENB): Used for fracture toughness evaluations.

4. How does surface preparation affect fatigue crack growth results?

Surface finish, residual stresses, and machining quality significantly impact crack initiation and propagation. Specimens should have a fine-polished surface (e.g., 600-grit or finer) to eliminate machining marks and avoid premature failure due to stress concentrations.

5. Why is the notch shape and size important in FCG testing?

The notch acts as a stress concentrator to initiate crack growth in a controlled manner. The notch should be precisely machined and conform to test standards, ensuring repeatability and reliable data for crack growth rate analysis.

Looking for Fatigue Crack Growth (FCG) testing services in India? Get accurate, NABL-certified material testing with advanced Universal Testing Machines (UTMs) today!

Registration & Certifications

We are a certified and registered organization committed to quality and compliance.

Accredited by NABL

(National Accreditation Board for Testing and Calibration Laboratories – India)

Our laboratory is accredited by NABL as it meets international standards for quality and competence.

It operates in accordance with ISO/IEC 17025:2017. NABL accreditation is recognized

both nationally and internationally.

If you are looking for NABL-accredited testing laboratories in India, our facility provides high-precision testing services in compliance with global quality standards

- Tensile Testing: ASTM E8M, ASTM E21, ASTM B557M, ASTM A770, ASTM D3039M, ASTM D412, ASTM D638, IS 1608 (Part-1, Part-3), ISO 6892

- Compression Testing: ASTM D575

- Bend Testing: ASTM E290, IS 1599

- Low Cycle Fatigue Testing: ASTM E606

- High Cycle Fatigue Testing: ASTM E466

- Fatigue Crack Growth Rate Testing: ASTM E647

- Fracture Toughness Testing (KIC): ASTM E399

- Fracture Toughness Testing (JIC): ASTM E1820

- Creep & Stress Rupture Testing: ASTM E139, ASTM E292

AS9100:2016 Certified

MIC Labs is certified by IAS in accordance with AS9100:2016, meeting international aerospace quality standards.

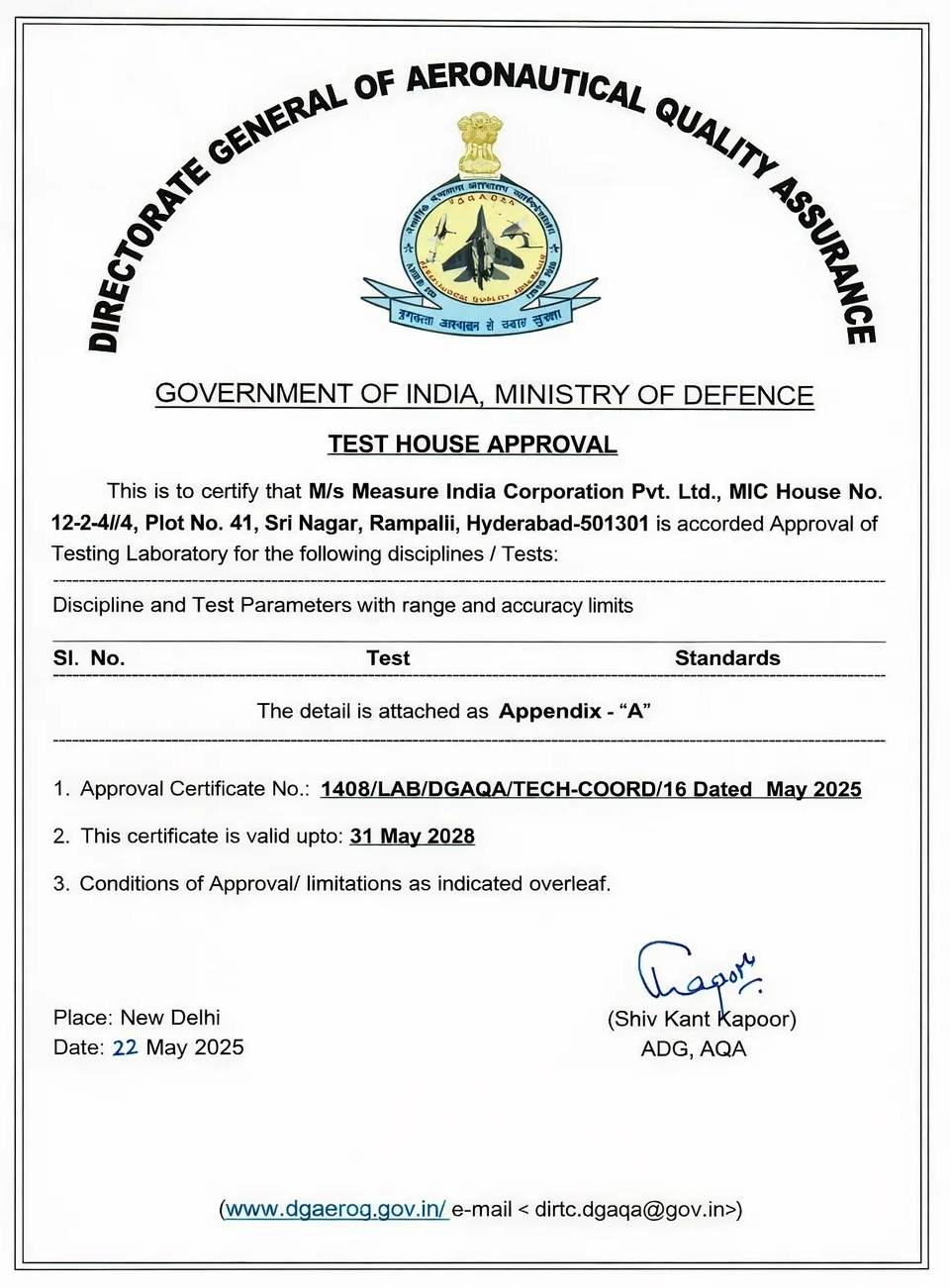

Approved by DGAQA

MIC Labs is approved by DGAQA, ensuring compliance with aerospace and defense testing requirements.

Registered by UDYAM

Measure India Corporation Pvt Ltd is UDYAM registered, recognizing us as a certified MSME in India.

This registration highlights our commitment to quality, statutory compliance, and industry standards.

Why Choose Us

We have 20 years of experience in providing material testing systems and offering testing services with great confidence.

- 90+ Products

- 500+ Customers

- 35+ Team Size

- Expertise in guiding and working with top-notch researchers and engineers

- World-class mechanical testing laboratory

Mechanical Testing Lab Services & Universal Testing Machines Suppliers in India

“With over 20 years of experience, Measure India Corporation Pvt Ltd supplies Universal Testing Machines & mechanical testing services, ensuring precision, reliability, and compliance with ASTM, ISO, and global standards across various industries.”

Contact Information

9:00 AM – 5:30 PM

Sreenagar, Rampally,

Hyderabad, Telangana 501301

Get In Touch With Us

Please fill out the form below and a member of our team will respond promptly.