Specifications

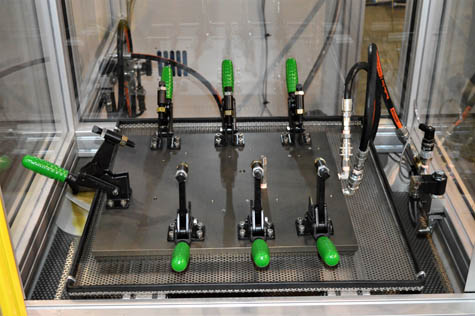

The standard test frame has an internal testing chamber that is 24 inches deep by 33 inches wide by 44 inches tall. Pressurization will be with an oil over water, servo-controlled intensifier powered by a hydraulic power supply. Part filling and pressure intensifier charging will be with a low pressure, high flow pump that will pump through an indicated filter. All reservoirs will have low level switches to turn off pumps, and highlevel switches to shut down the systems in case of an overflow/overfill situation. The test stand will have a pressure and temperature sensor on the inlet side of the test piece. The chamber includes a safety glass door with integrated safety locks, a single point pressure connection port for connecting to test components or sealing the fixture. ITC equipment meets all OSHA requirements for operator safety. Interlaken is a UL508A panel shop. All electrical equipment is UL/ULC labeled. The design of the equipment gives careful consideration to ergonomics and minimizing environmental stress.

Pressure transducers will be used to control the pressure coming from the pressure intensifier and also for monitoring and data collection. The pressure transducer used for data collection during the testing will have specifications as shown below.

| Accuracy | ±0.10% full scale |

|---|---|

| Linearity | ±0.10% full scale |

| Hysteresis | ±0.05% full scale |

| Media | All gases/liquids compatible with wetted parts |

| Resolution | Infinite |

| Calibration | 5-point calibration: 0%, 50%, and 100% of full scale |