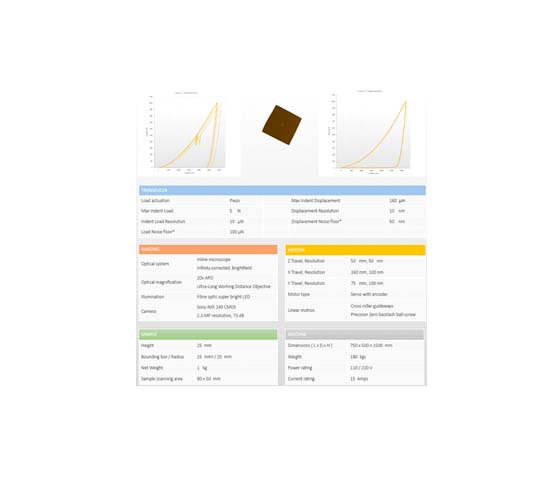

Specifications

- Automatic Calculation of

- Vickers Hardness

- Martens Hardness

- Indentation Hardness

- Young’s Modulus

- Reduced Modulusz

- Indentation Creep

- Indentation Relaxation

- Contact area

- Contact depth

- Feedback control modes – Load and Displacement. Indent functions:

- Standard Function

- Trapezoid Function

- Partial Load-Unload Function

- Complete Unload Function

- Automated testing

- Fully automated Z, T & Y motion control

- Multi indent based on user defined pattern

- Testing In accordance with ISO 14577-1 and ASTM E2546

- DeepSense Testing and Analysis software provides

- 2D and 3D Modulus and Hardness surface mapping

- Real time load-displacement plots

- Selectable Data acquisition rate – 500 Hz, 1 kHz, 2 kHz, 4 kHz*

- Results exportable to excel, csv, pdf and image files

- Sample Auto-Focus to quickly locate regions of interest

- Extended Depth of Focus to get crisp indentation images

- Built-in Self Calibration tools

- Flexible reporting format

- Dual cantilever flexure indentation mechanism draws inspiration from compliant mechanisms. Carved out of a single metal block, backlash errors are reduced to a minimum. Higher rotational stiffness is ensured by double cantilever which minimises roll. Perfectly straight motion of the flexure ensures Yaw & Roll errors are negligible, which is essential to make sure the indenter tip is always perpendicular to the sample surface

- Acoustic and Vibration damping to operate in a stable environment

- Translation stages with sub-micron accuracy for precise sample positioning and repeatability

- Granite load frame, high rigidity more than 108 N/m

- Range of indenters – Berkovich, Modified Berkovich, Micro Vickers, Conical & Ball

- Versatile EtherCAT based controller with multiple ADC and DAC channels for high speed and precise control

DeepIndent - Highlights

- Loading force ranges between 100mN to 5 N with Resolution - 1mN

- Displacement range Max up to 100 Microns with resolution 10 Nanometres

- DeepIndent adapts to ISO 14577- 2

- Upright Metallurgical Microscope for highly magnified and sharp images

- Stages with large translation and sub-micron resolution for precise sample positioning

- Custom instrument enclosure and passive damping system to operate in a stable environment independent of external condition

- Automated testing with user friendly interface

DeepSense Software

DeepSense, the user-friendly interface developed for DeepIndent allows the automatic acquisition of test data and Real-time data graphs.

Self-calibration and auto tuning features are robust tools built-in to enhance the output with minimum intervention of the user.

The inbuilt indent patterns are incorporated to reduce the indent time that helps the user to perform more number of tests in short time

- Load vs Displacement graph

- Load vs Time graph

- Displacement vs Time graph

- Vickers Hardness

- Indentation Hardness

- Young’s Modulus

- Reduced modulus

- Contact area

- Contact depth

- Test raw data

- 2-D plots of hardness variation over an area

DeepIndent Specifications

Transducer Specification:

- Load Range - 100mN to 5 N, Resolution 1mN

- Displacement range up to 100 Micrometre, Resolution 10 nm

Optics Specification:

- Optical System - Infinity color corrected, Bright field.

- Light Source - LED, Long working distance objectives.

- Optical Magnification - 20x (Other magnifications are optional)

- Camera - USB 0, C-Mount with 1/1.2” CMOS sensor.

Stage Specifications:

- Stages using servo motor with resolver.

- Travel X – 150mm,

- Y – 50 mm,

- Z – 75 mm.

- Resolution - 100 nm

DeepSense Software Features:

- User-friendly interface for handling the machine.

- Real-time data graphs

- Self-calibration tool

- Auto tuning feature

- Inbuilt indent pattern options

- Results in excel, csv, pdf, image format