Specifications

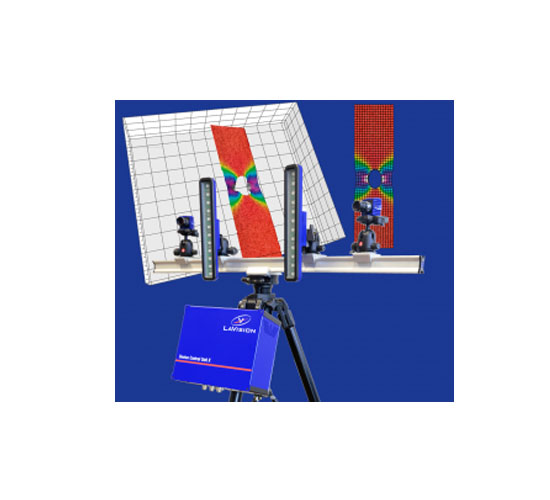

With vast experience in the area of scientific imaging systems and Digital Imaging Correlation (DIC), LaVision provides the ultimate in quality and performance for your materials measurements needs. Comprehensive service and support is given throughout the life of the product via our factory trained engineers

- High accuracy measurements of deformation and strain

- Sensitive Imager E-Lite cameras combined with quality lenses

- Ultra-rigid and lightweight mounting system

- Equivalent to thousands of gauges on the specimen surface

- Validate finite element simulations

- Suitable in standard and harsh environments

- Exceptional strain range – from micro strains to 1000% strain

- Simple setup and calibration procedure

- High strain rate impact through to long term fatigue testing

- Dedicated laptop computer controlling image acquisition, processing, and project management

- Highly efficient pulsed illumination system

- Fast and user friendly calculations

- Fixed frequency, manual trigger, and phase locked acquisition modes

- Virtual strain gauge mode

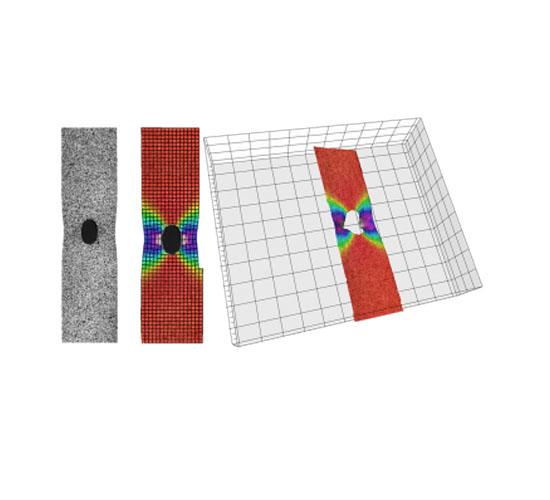

Matching Local Subset Pattern

Within the StrainMaster DIC software, a Least Squares Matching (LSM) approach with subset deformation is used to match the pattern in combination with higher order spline interpolation of the grey scale images.

Usually, the displacement field is calculated relative to the specimen in its undeformed state (typically the first image in the sequence). In cases where the deformation is relatively small the pattern in image N is matched directly back to the reference image. However, for large deformations the local pattern experiences significant changes and a sum of differential approach is used whereby the pattern is matched between successive images and then summed in a Lagrangian co-ordinate system.

Full Control

The DaVis platform offers complete hardware control with no need to rely on home-made triggering or separate multiple control porgrammes. It is possible to build acquisition loops specialized timing schemes.

- Standard and high speed cameras

- Data loggers for analogue data acquisition

- Translation stages

- Pulsed light sources

Phase locked recording of cyclic events such as fatigue testing is possible with the Strain Master controller and post-triggering of high speed events such as Split-Hopkinson pressure bar test is straightforward.

Operating in live mode or as a post-process, it is possible to apply virtual strain gages to the specimen surface. This approach using optical techniques has several advantages over conventional devices:

- Non-contacting

- No need to choose extensometer position before the test

- Does not get damaged if specimen breaks

- Can be used for specimen in solutions or in environmental chambers

Crack Growth Analysis

Strain Master includes a crack growth analysis module to identify and track crack development in materials reporting crack length and crack opening.

This module works with non-speckled surfaces and the standard StrainMaster hardware.