Chemical Analysis Lab

We have extensive experience across a wide range of industries

Chemical Analysis Sample Preparation

Chemical analysis sample preparation is a critical step in obtaining accurate and reliable test results. At MIC Labs, the process begins with collecting a representative sample to ensure precise chemical composition analysis. Large samples are then cut and sectioned into smaller, manageable pieces before undergoing grinding or milling to achieve a fine, homogeneous powder. This uniformity is essential for consistent analysis. To prevent contamination, samples are thoroughly cleaned to remove any surface impurities such as oils or oxidation. Depending on the testing method, the sample may be dissolved in acids or alkalis for wet chemical analysis, fused with lithium borate for X-Ray Fluorescence (XRF), or compressed into pellets for spectroscopy techniques like LIBS (Laser-Induced Breakdown Spectroscopy). Each preparation step adheres to ASTM, ISO, and IS standards, ensuring high precision and repeatability. Proper sample preparation enhances the reliability of chemical analysis, supporting industries such as aerospace, automotive, and metallurgy in making data-driven decisions.

Chemical Analysis Sample Preparation – FAQs

1. Why is sample preparation important in chemical analysis?

Sample preparation ensures that the material is uniform, contamination-free, and in the correct physical state for accurate testing. Proper preparation enhances repeatability and reliability in results, making it a crucial step in chemical analysis.

2. What methods are used to prepare samples for chemical analysis?

The preparation method depends on the type of material and the analysis technique. Common methods include cutting and sectioning, grinding and milling, dissolution (acid digestion), fusion (for XRF analysis), and pelletizing (for spectroscopy techniques like LIBS and XRF).

3. How does contamination affect chemical analysis results?

Contamination can alter the actual composition of the sample, leading to incorrect results. To prevent this, samples are carefully handled, cleaned, and prepared using non-reactive tools and controlled environments.

4. What standards are followed for chemical analysis sample preparation?

Sample preparation at MIC Labs follows internationally recognized standards such as ASTM, ISO, and IS, ensuring precision, accuracy, and repeatability in chemical testing.

5. How is sample preparation different for metals, polymers, and ceramics?

- Metals require cutting, grinding, and sometimes acid digestion for precise elemental analysis.

- Polymers may involve solvent dissolution or thermal treatments to break down their structure for analysis.

- Ceramics and minerals often undergo fusion or pelletizing techniques to ensure even dispersion of elements during testing.

Looking for tensile testing services in India? Get accurate, NABL-certified material testing with advanced Universal Testing Machines (UTMs) today!

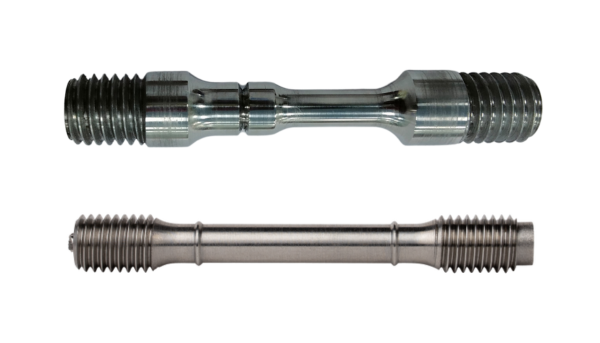

Chemical Analysis Gripping Process

The gripping process in chemical analysis refers to how a sample is securely held or prepared for different testing techniques to ensure accurate and consistent results. At MIC Labs, proper gripping methods are followed based on the material type, sample size, and analysis technique.

For solid samples, precision cutting and sectioning are performed to create uniform pieces that fit securely into the analysis instrument. In cases like X-Ray Fluorescence (XRF) or Optical Emission Spectroscopy (OES), samples are either clamped onto the instrument stage or mounted in specialized holders to ensure stability during testing. Powdered samples are often pelletized using high-pressure presses to form solid discs, allowing for better handling and improved measurement accuracy.

For wet chemical analysis, liquid samples are prepared through dissolution, filtration, or dilution before being securely held in test tubes, cuvettes, or crucibles to prevent spillage and contamination. In high-precision analysis techniques such as ICP-OES (Inductively Coupled Plasma Optical Emission Spectroscopy) or AAS (Atomic Absorption Spectroscopy), sample holders and automatic samplers are used to grip and transfer the solution for testing efficiently.

By ensuring proper gripping and handling, MIC Labs minimizes errors and enhances the precision of chemical analysis across various industries, including aerospace, automotive, and materials research.

Chemical Analysis Gripping Process – FAQs

1. Why is proper gripping important in chemical analysis?

Proper gripping ensures that the sample remains stable and securely positioned during testing, preventing movement that could lead to inaccurate results. It also helps in achieving uniform measurements, reducing errors caused by misalignment or contamination.

2. How are solid samples gripped for chemical analysis?

Solid samples are usually clamped, sectioned, or mounted in specialized holders, depending on the testing method. For techniques like X-Ray Fluorescence (XRF) and Optical Emission Spectroscopy (OES), samples must be firmly held in place to ensure accurate readings.

3. How are powdered samples prepared for analysis?

Powdered samples are typically compressed into pellets using a high-pressure press, which provides a stable and uniform surface for analysis. In some cases, powders are mixed with binders or fused into glass beads to improve consistency for techniques like XRF.

4. What precautions are taken to prevent sample contamination during gripping?

To avoid contamination, non-reactive tools and clean surfaces are used when handling samples. For liquid samples, chemically resistant containers such as glass cuvettes, crucibles, or test tubes are used to ensure purity and prevent interaction with the sample.

5. How is the gripping process different for liquid samples?

Liquid samples are typically held in test tubes, cuvettes, or automated sampling trays to ensure consistent volume and prevent evaporation. For methods like ICP-OES (Inductively Coupled Plasma Optical Emission Spectroscopy) or AAS (Atomic Absorption Spectroscopy), specialized pumps and sample holders help in precise analysis.

Looking for tensile testing services in India? Get accurate, NABL-Certified material testing with advanced Universal Testing Machines (UTMs) today!

Chemical Analysis Testing Process

The chemical analysis testing process at MIC Labs is a structured procedure designed to determine the composition and properties of materials with high accuracy. It begins with sample collection and preparation, where solid samples are cut, ground, or milled, powders are pelletized or fused, and liquid samples are filtered or diluted. The next step involves selecting the appropriate analytical technique, such as X-Ray Fluorescence (XRF), Optical Emission Spectroscopy (OES), Inductively Coupled Plasma (ICP), Atomic Absorption Spectroscopy (AAS), Gas Chromatography (GC), or Wet Chemical Analysis, depending on the material type and testing requirements. Once the sample is prepared, it is securely placed in the instrument, ensuring proper gripping and contamination-free handling to obtain precise measurements. The instrument then analyzes the sample’s chemical composition, identifying elemental concentrations, molecular structures, or impurities. The collected data is carefully interpreted, validated, and compared against industry standards to ensure reliability and accuracy. Finally, a detailed test report is generated, providing insights into the material’s composition, compliance with regulations, and suitability for various applications in industries such as aerospace, automotive, defense, and metallurgy.

Chemical Analysis Testing Process – FAQs

1. What is the purpose of chemical analysis testing?

Chemical analysis testing is conducted to determine the composition, purity, and elemental or molecular structure of materials. It ensures quality control, regulatory compliance, and material verification in industries like aerospace, automotive, defense, and metallurgy.

2. What are the common methods used in chemical analysis?

Chemical analysis methods include X-Ray Fluorescence (XRF), Optical Emission Spectroscopy (OES), Inductively Coupled Plasma (ICP), Atomic Absorption Spectroscopy (AAS), Gas Chromatography (GC), and Wet Chemical Analysis. The selection depends on the material type and the required level of accuracy.

3. How is a sample prepared for chemical analysis?

Sample preparation varies based on the material type. Solids are cut, ground, or milled; powders are compressed into pellets or fused; and liquids are filtered or diluted to ensure consistency and prevent contamination during testing.

4. How is accuracy ensured in chemical analysis testing?

Accuracy is maintained through proper sample preparation, contamination-free handling, and calibration of instruments against certified reference standards. Additionally, multiple tests may be performed for verification.

5. How long does chemical analysis testing take?

The duration depends on the complexity of the material and the chosen testing method. Some techniques, like XRF or OES, provide results within minutes, while ICP, AAS, or chromatography-based methods may take a few hours due to sample preparation and data validation steps.

Looking for tensile testing services in India? Get accurate, NABL-certified material testing with advanced Universal Testing Machines (UTMs) today!

Registration & Certifications

Synergistically incentivize effective imperatives through fully researched intellectual capital. Appropriately fashion client-based.

Accredited by NABL

(National Accreditation Board for Testing and Calibration Laboratories – India)

Our laboratory is accredited by NABL as it meets international standards for quality and competence. It operates in accordance with ISO/IEC 17025:2017. NABL accreditation is recognized both nationally and internationally, ensuring the laboratory’s technical competence, impartiality, and reliability.

If you are looking for NABL-accredited testing laboratories in India, our facility provides high-precision testing services in compliance with global quality standards.

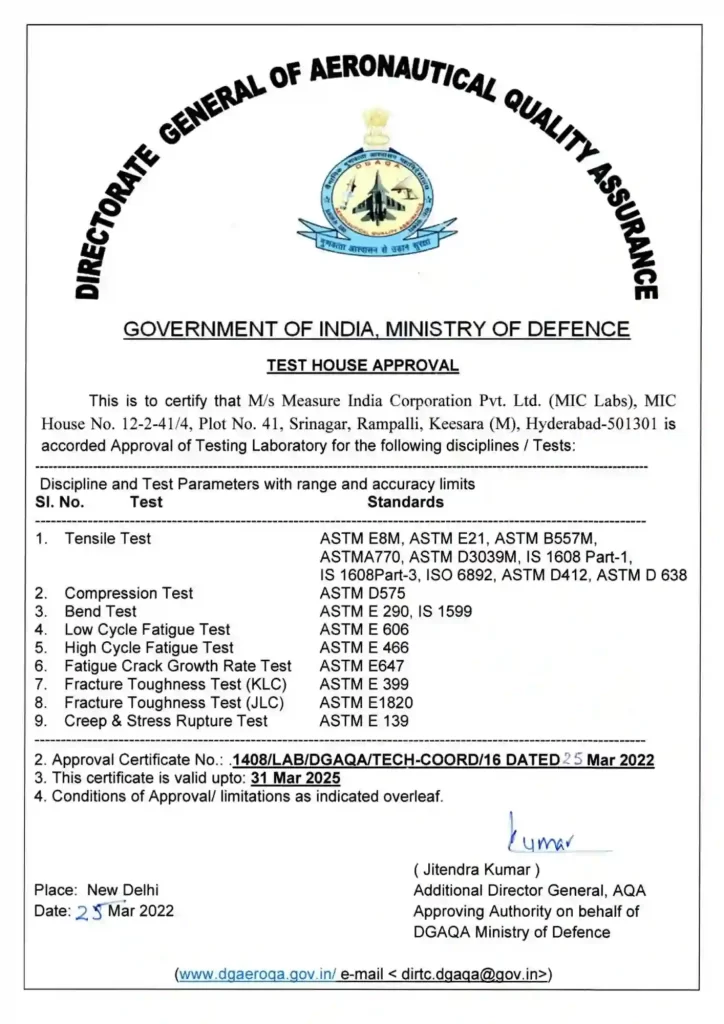

Tensile Testing (Standards: ASTM E8M, ASTM E21, ASTM B557M, ASTM A770, ASTM D3039M, IS 1608 Part-1, IS 1608 Part-3, ISO 6892, ASTM D412, ASTM D638)

Compression Testing (Standard: ASTM D575)

Bend Testing (Standards: ASTM E290, IS 1599)

Low Cycle Fatigue Testing (Standard: ASTM E606)

High Cycle Fatigue Testing (Standard: ASTM E466)

Fatigue Crack Growth Rate Testing (Standard: ASTM E647)

Fracture Toughness Testing (K₁C) (Standard: ASTM E399)

Fracture Toughness Testing (J₁C) (Standard: ASTM E1820)

Creep & Stress Rupture Testing (Standard: ASTM E139, E292)

AS9100:2016 Certified

( Integrated Assessment Services )

MIC Labs is certified by IAS in accordance with AS9100:2016, meeting international standards for quality and competence. AS9100:2016 is recognized both nationally and internationally, signifying a laboratory’s technical competence, impartiality, and reliability.

Approved by DGAQA

( Directorate General of Aeronautical Quality Assurance )

MIC Labs is approved by DGAQA ensuring that our laboratory meets the stringent standards required for testing in the aerospace and defense sectors. This approval reflects our technical competence and commitment to delivering reliable and precise results.

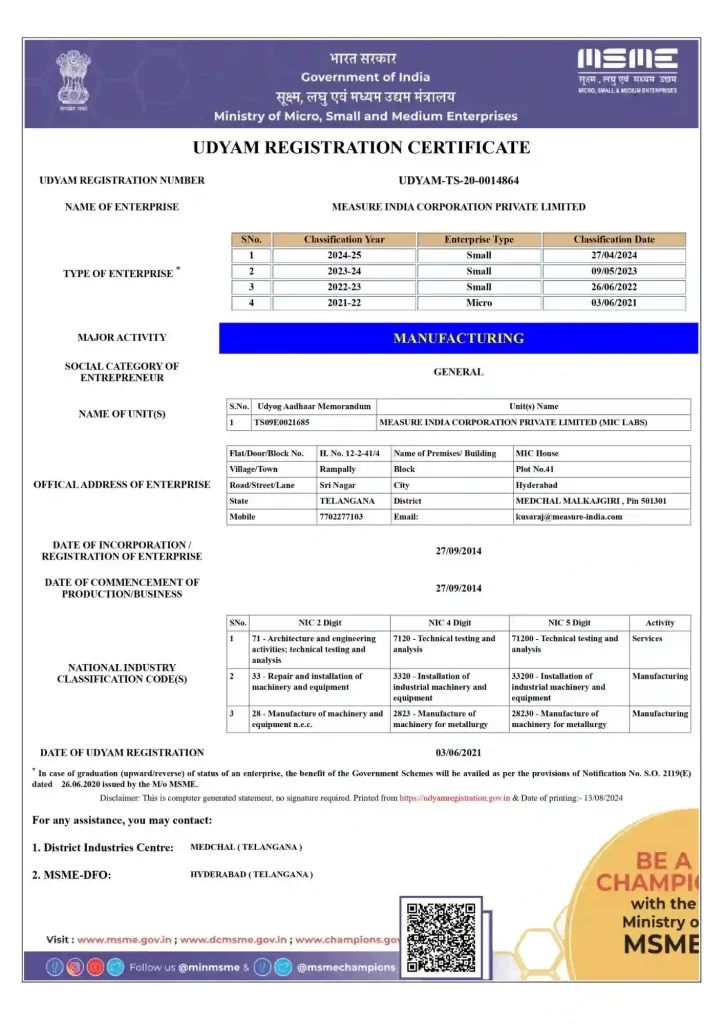

Registered by UDYAM

Measure India Corporation Pvt Ltd is UDYAM registered, recognizing us as a legitimate micro, small, or medium enterprise (MSME) in India. This registration highlights our commitment to quality and compliance with industry standards.

Why Choose Us

We have 20 years of experience in providing material testing systems and offering testing services with great confidence.

- 90+ Products

- 500+ Customers

- 35+ Team Size

- Expertise in guiding and working with top-notch researchers and engineers

- World-class mechanical testing laboratory

Mechanical Testing Lab Services & Universal Testing Machines Suppliers in India

“With over 20 years of experience, Measure India Corporation Pvt Ltd supplies Universal Testing Machines & mechanical testing services, ensuring precision, reliability, and compliance with ASTM, ISO, and global standards across various industries.”

Customer Satisfaction

Business Growth Every Year

500+

Active Clinets

Trusted Clients

Brands We Deal

Call us Now

For Universal Testing Machine: +91 99899 21114

Air Compressors: 96767 43939

Material Testing Laboratory : +91 91000 44532

Email Us

Email: info@measure-india.com

Opening Hours

From Monday – Saturday

9:00 am to 5:30 pm

Our Location

MIC House, Plot No 41, Srinagar, Rampally,

Hyderabad, Secunderabad, Telangana 501301

Get In Touch With us

We value your inquiries and feedback! Please fill out the form below, and a member of our team will respond to you promptly.