LaVision: 2D & 3D Digital Image Correlation (DIC) Systems Applications

The LaVision 2D & 3D Digital Image Correlation (DIC) Systems provide cutting-edge solutions for precise measurement and visualization of deformation, strain, and movement on material surfaces. These systems are widely used in research, development, and quality control across various industries due to their non-contact, full-field measurement capabilities.

1. Fundamental Materials Analysis

- Testing Methods:

- Tensile, compression, bend, fatigue, and impact testing.

- Accurate strain and deformation measurements for fundamental material behavior studies.

- Industries: R&D, manufacturing, and academia.

2. Component Behavior Under Loading

- Applications:

- Real-time observation and analysis of how components respond to mechanical loads.

- Provides critical insights for improving product design and performance.

3. Strain Hot Spot Identification

- Use Case:

- Detection of high-strain regions in complex structures, enabling targeted reinforcement or redesign to prevent failure.

4. Polymers and Composites

- Key Insights:

- Comprehensive analysis of deformation and strain in lightweight, high-performance materials.

- Essential for aerospace, automotive, and sports industries.

5. Flexible and Woven Materials

- Specialty Applications:

- Non-contact measurements for materials like textiles, woven composites, and foams under various load conditions.

- Industries: Textile manufacturing and soft material R&D.

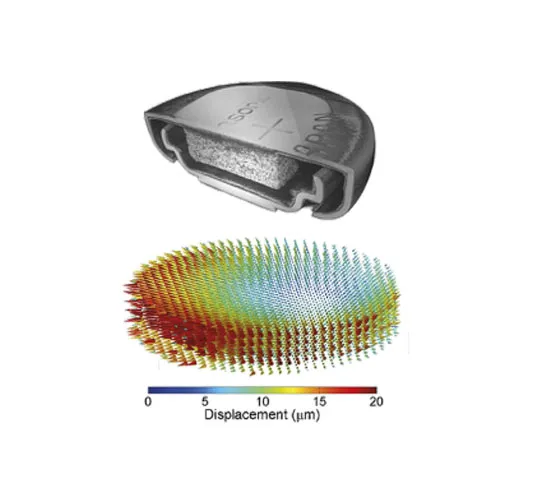

6. Biomedical Studies

- Applications:

- Analysis of biomechanical properties of tissues and synthetic devices.

- Used in prosthetics development, surgical simulations, and biomedical device validation.

7. Automotive Engineering Materials

- Use Cases:

- Study of engine parts, body panels, and crash dynamics.

- Supports durability testing and material optimization for automotive components.

8. Aerospace Component Testing

- Applications:

- Deflection analysis and strain mapping of aerospace parts, including wings, fuselage, and engine components.

- Ensures reliability under extreme operational conditions.