The ADMET MTEST Quattro® Material Testing Controller & Software is an innovative, versatile, and user-friendly PC-based solution designed to perform mechanical testing of materials, components, and products. Whether you’re testing static properties or dynamic fatigue, MTEST Quattro® provides a comprehensive platform with high-resolution input, fast sampling, and accurate control. It’s suitable for a wide range of industries, including aerospace, automotive, biomedical, and materials testing.

The MTEST Quattro® is used for a variety of mechanical testing needs, including tensile, compression, and fatigue tests for materials, components, and products. It is highly beneficial for industries requiring advanced testing, including aerospace, automotive, biomedical, and materials research.

universal testing machine accessories, universal testing machine price, ADMET accessories, MTEST Quattro®, material testing controller, fatigue testing, servo-hydraulic testing, mechanical testing software, retrofit testing machine.

The ADMET MTEST Quattro Material Testing Controller & Software is a cutting-edge system designed to control and manage universal testing machines for a wide range of material testing applications. This advanced testing solution provides comprehensive control over testing parameters, such as force, displacement, strain, and test speed, ensuring high-precision measurements and accurate results across various industries, including aerospace, automotive, manufacturing, and research.

The MTEST Quattro is known for its user-friendly interface and powerful functionality, making it suitable for both novice and experienced operators. It allows users to easily configure and run tests, providing seamless integration with a variety of universal testing machines. The intuitive software provides full control over the entire testing process, from setup to data acquisition and analysis, helping to optimize the efficiency and accuracy of material testing.

With its advanced capabilities, MTEST Quattro supports a wide array of test modes, including tension, compression, flexure, shear, and more. It is capable of conducting tests for a diverse range of materials, such as metals, polymers, composites, and elastomers. The software allows for real-time monitoring of test results, ensuring that any changes in material behavior can be detected and addressed immediately.

The MTEST Quattro software also features built-in reporting tools that automatically generate detailed test reports, including graphical representations of test data, making it easier for users to analyze material properties and evaluate performance. Additionally, the system is designed to handle multiple users, making it ideal for laboratory environments where several operators work on different tests simultaneously.

The ADMET MTEST Quattro Material Testing Controller & Software ensures superior data accuracy, high-speed performance, and enhanced automation capabilities, improving overall test reliability and productivity. With its easy-to-use interface and comprehensive features, it streamlines the testing process, reducing testing time and increasing throughput in any material testing environment.

For more information on the ADMET MTEST Quattro Material Testing Controller & Software, customization options, and universal testing machine price, contact us today.

The ADMET MTEST Quattro Material Testing Controller & Software is an advanced, versatile, and powerful solution for controlling material testing processes, offering seamless integration with ADMET universal testing machines and providing advanced features for real-time data acquisition, test programming, and detailed reporting.

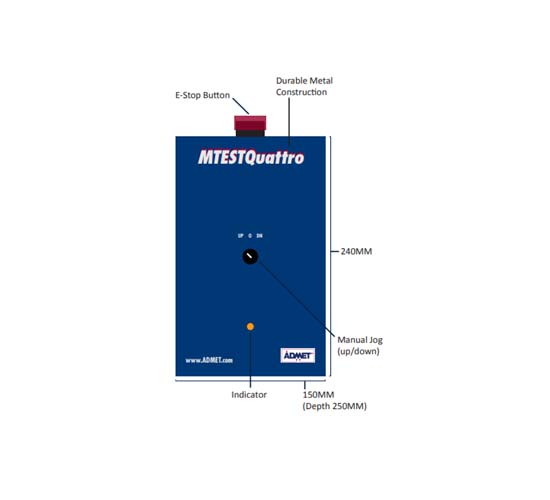

Overview: MTESTQuattro® is a versatile, PC-based solution for mechanical testing of materials, components, and products. It offers a flexible interface that provides connectivity to both electromechanical and servo-hydraulic testing systems and can retrofit or upgrade virtually any manufacturer’s testing machine, regardless of age or type.

The ADMET MTEST Quattro is a sophisticated material testing controller and software solution designed for use with Universal Testing Machines (UTMs) and other testing systems. It provides a comprehensive platform for controlling and monitoring mechanical tests, offering advanced features for data acquisition, analysis, and reporting. This high-performance controller and software combination is ideal for a wide range of industries that require precise testing of materials, components, and products.

Tensile Testing: The MTEST Quattro enables precise control and monitoring of tensile tests, allowing for the evaluation of tensile strength, elongation, and yield strength of materials such as metals, plastics, rubbers, and composites.

Compression Testing: The software supports compression tests, where materials are subjected to compressive forces to measure their compressive strength and modulus of elasticity. It is suitable for testing a variety of materials, including plastics, concrete, and foams.

Shear and Bending Testing: The MTEST Quattro controller and software are used for shear and bending tests, allowing users to evaluate the shear strength, flexural strength, and modulus of elasticity of materials like composites, polymers, and metals.

Fatigue and Endurance Testing: The software supports fatigue testing, which simulates cyclic loading conditions to evaluate the fatigue resistance and endurance limits of materials. This is particularly important in industries like aerospace, automotive, and biomedical engineering.

Stress-Strain Testing: The MTEST Quattro system provides real-time data acquisition during stress-strain testing, helping to measure the stress-strain curve, modulus of elasticity, and yield strength of materials such as metals, composites, and plastics.

Creep and Relaxation Testing: The software offers precise control for creep and relaxation tests, helping to determine the long-term deformation behavior of materials under constant stress. This is essential for testing materials like polymers, elastomers, and metals.

Adhesion and Peel Testing: The MTEST Quattro system is ideal for adhesion and peel tests, which are used to assess the bond strength of materials such as adhesives, coatings, and films. The system offers accurate control during peel and lap shear tests.

Thermal and Environmental Testing: The software integrates with environmental chambers to perform tests under varying temperature and humidity conditions. It is used to evaluate the performance of materials like plastics, composites, and metals under thermal stress.

Wire and Cable Testing: The MTEST Quattro is used for wire and cable testing, including tensile and elongation tests. It helps evaluate the mechanical properties of wires, cables, and other flexible materials, which are commonly used in telecommunications, electronics, and automotive industries.

Biomedical and Medical Device Testing: The system is widely used for biomaterial testing and medical device testing, where precise force control is required to simulate real-world conditions. It is ideal for testing biocompatible materials, medical implants, and prosthetic devices.

The ADMET MTEST Quattro Material Testing Controller & Software offers a comprehensive solution for controlling and monitoring tests across multiple industries. Its ability to handle complex testing requirements, coupled with high-precision data acquisition and advanced analysis features, makes it a vital tool for testing materials, components, and products. Whether testing for fatigue, tensile strength, or adhesion, the MTEST Quattro provides a versatile, reliable, and user-friendly platform for achieving accurate results.

The ADMET MTEST Quattro Material Testing Controller & Software is a state-of-the-art control system designed for material testing applications. It integrates hardware and software to offer precise control, monitoring, and data analysis for a wide range of material testing machines. The MTEST Quattro allows users to set up, conduct, and analyze tests in real-time, offering a seamless testing experience across various industries.

The ADMET MTEST Quattro operates by connecting with material testing machines to control test parameters such as force, displacement, and strain. It provides real-time feedback, allowing users to adjust test settings and monitor results as tests are conducted. The integrated software allows for data logging, test automation, and customizable test protocols, ensuring accurate and repeatable results across different test materials.

The ADMET MTEST Quattro is compatible with a wide variety of mechanical tests, including:

Torsion testing

It can be used for testing materials like metals, polymers, composites, and textiles in industries such as automotive, aerospace, and manufacturing.

Key features of the ADMET MTEST Quattro include:

Versatile compatibility with different testing machines and accessories.

Yes, the ADMET MTEST Quattro can be easily integrated with many existing material testing machines. It is designed to be compatible with a wide range of load frames, grips, extensometers, and other accessories. The controller connects to the machine’s sensors and provides seamless integration for precise control and data acquisition during testing.

The ADMET MTEST Quattro is used across various industries for material testing applications, including:

Research and development (for innovative material testing and experimentation).

The ADMET MTEST Quattro features an intuitive, user-friendly interface that makes it easy for users to set up, monitor, and analyze tests. The software allows users to control all aspects of the test, including parameters like load, speed, and displacement, and offers real-time graphical displays of test progress. The interface is designed to minimize complexity while providing the depth of functionality needed for accurate material testing.

Yes, the ADMET MTEST Quattro is capable of controlling high-speed testing applications. Its advanced software allows for precise control over high-speed tests, ensuring accurate data collection even in dynamic conditions. It is suitable for testing materials that require fast load application, displacement, or stress rates, and can be used for both static and dynamic testing environments.

Yes, the ADMET MTEST Quattro is well-suited for fatigue testing and durability testing. The system allows users to program cyclic loading conditions and monitor test parameters over extended periods, making it ideal for evaluating the performance of materials under repetitive stress or load cycles.

To maintain the ADMET MTEST Quattro:

Backup data regularly to prevent loss of test results.

The ADMET MTEST Quattro typically comes with a one-year warranty covering manufacturing defects and hardware issues. Extended warranties may be available depending on the configuration and the customer’s needs.

The maximum load capacity of the ADMET MTEST Quattro depends on the connected material testing machine. It is compatible with testing machines that can handle load capacities ranging from a few kN to several hundred kN, depending on the model and application.

Yes, the ADMET MTEST Quattro software can automatically generate detailed test reports. After a test is completed, the system can produce comprehensive reports containing data analysis, graphs, and results, which can be easily exported to various file formats such as PDF and Excel for further analysis or documentation.